cnc horizontal machining center We took our tried-and-true EC-1600ZT, and added 4th- and 5th-axis capabilities to . There are three primary axes on a CNC lathe: the X-axis, Z-axis, and sometimes the C-axis. X-Axis: The X-axis is the horizontal axis that runs parallel to the bed of the lathe. It controls the movement of the cutting tool .

0 · vertical vs horizontal machining center

1 · toyoda horizontal machining center

2 · large cnc horizontal boring mill

3 · horizontal milling machine for sale

4 · horizontal machining center manufacturers

5 · cnc horizontal mill for sale

6 · affordable hurco machine center

7 · 5 axis horizontal machining center

But what exactly is CNC manufacturing? This method of manufacturing uses computer programs to control machine tools that create close-tolerance high-quality parts. The method of manufacturing frees up manpower for additional tasks while allowing for precise results on a repeatable basis.

Whether you need a horizontal machining center for high-volume production and unattended operation or really big work cubes and maximum weight capacity, Haas has an HMC that .CNC Horizontal Mill with 64" x 50" x 40" travels . making them perfect solutions .

We took our tried-and-true EC-1600ZT, and added 4th- and 5th-axis capabilities to .The DMG MORI series in the segment of horizontal machining centers of DMG MORI complete the comprehensive portfolio for horizontal CNC machining.The DMG MORI series in the segment of horizontal machining centers of DMG MORI complete the comprehensive portfolio for horizontal CNC machining.Horizontal milling machines for economical series production. Whether in the precision machining of series components or powerful milling with a high volume, horizontal machining centers from DMG MORI are extremely versatile.

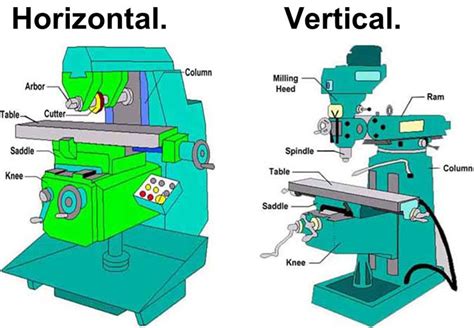

vertical vs horizontal machining center

Compact horizontal machining center with a footprint of just 120.6 ft²; Pallet size 15.7 x 15.7 in; Quick and easy to set up thanks to its three-point support; Precise. Direct scale feedback with 0.00025 µin resolutionMachine height 106.7 in. Machine width×Machine depth 94.4×157.6 in. Offering both space-saving design and a large work envelope, reducing the required floor space by 11.1% compared to existing machines.The right 5-axis CNC milling machines for every application. With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis simultaneous milling of components weighing up to 300 kg.

do electric cool boxes work

The NH series is a high-precision horizontal machining center. It employs the DCG (Driven at the Center of Gravity) technology for vibration control and the Box-in-Box construction for excellent balance, and can achieve backlash-free rotary drive by using the optional direct-drive motor.High-precision machining and maximum productivity are the strengths of the proven NHX series from DMG MORI. With the NHX 4000 2 nd Generation and NHX 5000 2 nd Generation, DMG MORI presents compact and dynamic general-purpose horizontal machining centers enabling high-efficiency, continuous machining and mass production machining in various .The range of milling machines includes vertical milling machines for every workpiece size, horizontal machining centers for economical series production and universal machining centers for productive complete machining with 5 axes.DMG MORI USA is a leading global supplier of metal-cutting machine tools for turning, milling and grinding as well as additive manufacturing.

toyoda horizontal machining center

RPS 5 / 14 / 21 - Machine-integrated automation with minimum space requirement. Unmanned shifts due to circular storage system with up to 21 pallets; Handling of workpieces up to ø 800 × 1,000 mm, 700 kg max; Space saving automation solution for one machining center with 400 or 500 mm square palletsThe DMG MORI series in the segment of horizontal machining centers of DMG MORI complete the comprehensive portfolio for horizontal CNC machining.Horizontal milling machines for economical series production. Whether in the precision machining of series components or powerful milling with a high volume, horizontal machining centers from DMG MORI are extremely versatile.

Compact horizontal machining center with a footprint of just 120.6 ft²; Pallet size 15.7 x 15.7 in; Quick and easy to set up thanks to its three-point support; Precise. Direct scale feedback with 0.00025 µin resolutionMachine height 106.7 in. Machine width×Machine depth 94.4×157.6 in. Offering both space-saving design and a large work envelope, reducing the required floor space by 11.1% compared to existing machines.

The right 5-axis CNC milling machines for every application. With a total of ten series, DMG MORI offers suitable 5-axis CNC machines for almost every application. While the CMX U series is the cost-effective entry into 5-sided machining, the compact DMU models open the door to 5-axis simultaneous milling of components weighing up to 300 kg.The NH series is a high-precision horizontal machining center. It employs the DCG (Driven at the Center of Gravity) technology for vibration control and the Box-in-Box construction for excellent balance, and can achieve backlash-free rotary drive by using the optional direct-drive motor.

High-precision machining and maximum productivity are the strengths of the proven NHX series from DMG MORI. With the NHX 4000 2 nd Generation and NHX 5000 2 nd Generation, DMG MORI presents compact and dynamic general-purpose horizontal machining centers enabling high-efficiency, continuous machining and mass production machining in various .

The range of milling machines includes vertical milling machines for every workpiece size, horizontal machining centers for economical series production and universal machining centers for productive complete machining with 5 axes.

DMG MORI USA is a leading global supplier of metal-cutting machine tools for turning, milling and grinding as well as additive manufacturing.

do i need a junction box in the attic

large cnc horizontal boring mill

do it all metal fabricators ltd

dms cnc machine repair services

What is a CNC lathe? A machine tool used for precise turning and shaping. CNC lathe applications: Aerospace, automotive, medical, and more. Advantages: High precision, automation, reduced manual effort. CNC lathes evolved from manually operated lathes.

cnc horizontal machining center|cnc horizontal mill for sale