electrical pull box sizing calculator Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. With its round corners and smooth edges, our Drawn Steel Junction Box ensures utmost safety and reliability in exposed work applications. Whether you're installing light fixtures, switches, or receptacles, our box is meticulously designed to meet your specific needs.

0 · nec junction box size chart

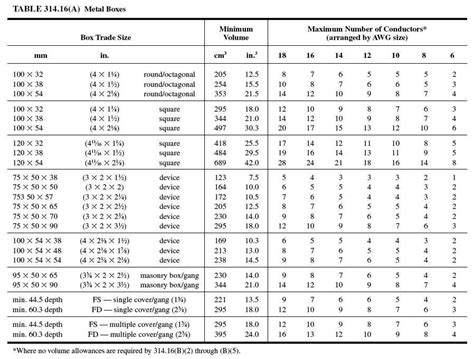

1 · electrical underground pull box sizing

2 · electrical pull box size chart

3 · electrical junction box size calculator

4 · electrical box sizing formula

5 · electrical box sizing chart

6 · electrical box size calculation

7 · 314.28 pull box calculator

Our complex transmission components make a big contribution to ideally meeting the requirements for fuel efficiency, comfort and dynamics.

nec junction box size chart

Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box .Using improper equipment to house your underground electrical systems can lead .The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in .

This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According . Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

1956 ford f100 sheet metal

Effortlessly calculate the required electrical pull box size for your wiring project using our Electrical Pull Box Size Calculator. Input the number of conductors and select the box type to get . Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves .

When sizing pull boxes and junction boxes, follow these suggestions: Step 1: Organize and always draw out the problem. Step 2: Calculate the horizontal distance(s):For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example.Calculating the minimum dimensions of a box containing straight pull(s) is quite simple: multiply the trade size (metric designator) of the largest raceway by eight. For example, calculate the minimum dimension for a pull box with two 2-inch .

Determine both the 600 Volt and Medium Voltage calculations to estimate and manage cable installation projects. Use this simple tool to calculate conduit size and fill percentage, pulling .Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact .The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull.This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According to the NEC (National Electrical Code), different rules apply for straight and angle pulls.

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

Effortlessly calculate the required electrical pull box size for your wiring project using our Electrical Pull Box Size Calculator. Input the number of conductors and select the box type to get accurate results. Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side. When sizing pull boxes and junction boxes, follow these suggestions: Step 1: Organize and always draw out the problem. Step 2: Calculate the horizontal distance(s):For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example.

Calculating the minimum dimensions of a box containing straight pull(s) is quite simple: multiply the trade size (metric designator) of the largest raceway by eight. For example, calculate the minimum dimension for a pull box with two 2-inch conduits.Determine both the 600 Volt and Medium Voltage calculations to estimate and manage cable installation projects. Use this simple tool to calculate conduit size and fill percentage, pulling tensions, cable sidewall pressure, jam probability, voltage drop, ground wire sizing, and more.Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact .

The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull.This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According to the NEC (National Electrical Code), different rules apply for straight and angle pulls.

electrical underground pull box sizing

electrical pull box size chart

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

Effortlessly calculate the required electrical pull box size for your wiring project using our Electrical Pull Box Size Calculator. Input the number of conductors and select the box type to get accurate results. Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side. When sizing pull boxes and junction boxes, follow these suggestions: Step 1: Organize and always draw out the problem. Step 2: Calculate the horizontal distance(s):For conductors 4 AWG and larger, pull boxes and junction boxes must be sized in accordance with NEC article 314.28. This post will provide an overview of the sizing rules for the most common types of pulls, along with a calculation example.

Calculating the minimum dimensions of a box containing straight pull(s) is quite simple: multiply the trade size (metric designator) of the largest raceway by eight. For example, calculate the minimum dimension for a pull box with two 2-inch conduits.

1960 chevy bel air sheet metal

View credits, reviews, tracks and shop for the 1994 CD release of "Blackbox (Wax Trax! Records: The First 13 Years.)" on Discogs.

electrical pull box sizing calculator|electrical box sizing chart