sheet metal bend tolerances Tolerances – The feature to feature tolerance on for the laser cutter is +/-.004" but is typically held much closer. The smallest cut possible is dictated by the width of the beam or .008" wide. Mandrini e frese affidabili e resistenti per macchine CNC, così da lavorare con utensili perfettamente equilibrati. Tooltarget, spedizioni in 24 ore.

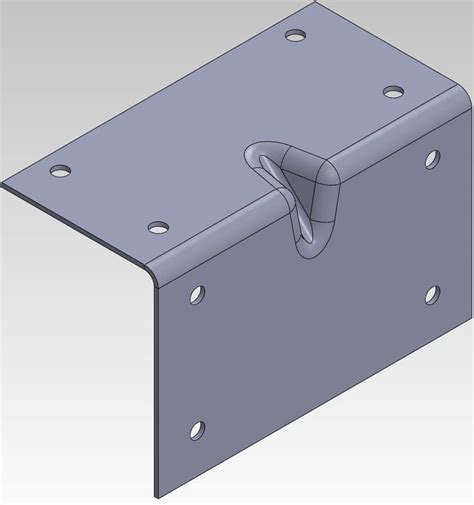

0 · sheet metal gusset design guidelines

1 · sheet metal dimensioning standards

2 · sheet metal design guidelines pdf

3 · sheet metal bending chart

4 · sheet metal bending basics

5 · sheet metal bend relief guidelines

6 · minimum flange length sheet metal

7 · maximum thickness sheet metal bending

Designed with integrated reinforcing steel mesh grid for poured concrete infills. Perfect for a wide range of concrete applications. Galvanized or Stainless Steel. 27 Frame Sizes & 6 Tray Depths. Multi-Cover Versions Available. H15 thru HS25 Load Ratings

Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication.

Proper tolerancing for sheet metal bending jobs is important for making your designs ready for manufacturing. This post will briefly explain where the variations come from, and what the .

The strength of the sheet metal bend needs to be ensured during the bending process, and it is generally weaker for long and narrow bends, while short and wide bends are .

Tolerances – The feature to feature tolerance on for the laser cutter is +/-.004" but is typically held much closer. The smallest cut possible is dictated by the width of the beam or .008" wide.

Sheet metal is a slightly less precise method of manufacturing that relies on the cutting, bending, and stretching of thin sheets of metal to produce a final geometry. The looser tolerances achieved by the sheet metal method are .

We account for +/- 0.02” bend to bend, with a maximum allowable tolerance of +/- 0.03”—the maximum cumulative tolerance of a part with multiple formed features. Sheet Metal Part Design for Manufacturing Tip Punching of a sheet metal part Bending (Forming) Sheet metal pieces are usually cut, punched and then bent (order may vary depending on the features). Bending involves a punch, a die and the work part. The sheet meal . 3 Sheet Metal Part Design for Manufacturing Tip. 3.0.1 DESIGNING FEATURES TOO CLOSE TO THE BEND; 4 A Note on Tolerance Stack-Ups; 5 Precision Sheet Metal Tolerance FAQ. 5.0.1 Why is tolerancing . Uncover the basics of sheet metal tolerances, including measurement methods and industry standards for perfect parts. About. 360° Virtual Factory Tour . and bending. To achieve the required sheet metal .

Actual tolerances in sheet metal fabrication are influenced by various factors, underscoring the necessity of engaging with your fabricator at the initial stages of design. . Sheet Metal Process - Sheet Bending. CNC sheet bending involves the use of press brakes to manipulate sheet metal into desired shapes. While tooling is a fundamental .Consulting with an experienced sheet metal fabricator can help you better understand tolerances in sheet metal bending processes. Tonnage - Factors such as bend radius, material properties, material type and bend length all contribute to how much pressure is required to make a particular bend. As mentioned, presses have a maximum tonnage .In sheet metal bending, the K-factor is a crucial parameter that determines the amount of material elongation and deformation during the bending process. It is a constant value used to calculate the bend allowance, which helps determine the final dimensions of the flat sheet before bending.

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die). Bending can improve a part’s structural integrity by increasing part stiffness, redistributing stress within a part, and help .General dimensional tolerances for parts formed by press working from sheet metal Basic size step Grades G rad eA B C Over 1000 to 2000 incl. Over 400 to 1000 incl. . Note:Grade A, B and C are equal to tolerance grade f, m and c of JIS B 0405 respectively. Table 2. adimensional tolerance of bending and drawing Unit:mm A BG rad eC Grades Basic . Now consider 16-gauge mild steel. The sheet has a nominal thickness of 0.059 in., an upper limit of 0.0648 in., and a lower limit of 0.0548 in., giving us a range of 0.010 in. Add this to the 0.002-in. depth-of-penetration variation noted earlier, and . Unlock the secrets to mastering sheet metal tolerances and ensure precision in your manufacturing processes. Explore the key factors that contribute to top-notch engineering results. . Limit Deviation of Unnoted Tolerances (Punching, Cutting, Bending) Angles. Unit: mm. 8. Selection of Angular Tolerance Level. Unit: mm. 9. Unnoted Flatness and .

Edge to edge, or hole to hole, or Edge or hole to bend* Bend to bend* Angular Tolerances edge to hole. ( NO BEND AREA) FLAT 0.25" or less (6.0mm or less) over 0.25" to 1" incl. (over 6mm to 25mm) over 1" to 5" incl. (over 25mm to 127mm) over 5" to 16" incl. (over 127mm to 406mm) over 16" to 40" incl. (over 406mm to 1016mm) over 40" to 90" incl .

cnc end mill grinding machine

Dxf/flat pattern - the issue here is that your flat pattern will change depending on your sheet metal parameters (bend radius, k factor, bend deduction etc). The sheet metal parameters are dependent on the machines & tooling that will be used to bend the parts, which is far from universal between different manufacturers. 3D files - this is the .

Learn how to find bend angle tolerance specifications for each material. Keep in mind that metal and plastic material have different tolerance considerations. Learn more about bending plastic. Dimensional tolerances for single bends. At SendCutSend, simple, single flange parts will have a +/- 0.015” dimensional tolerance, bend to edge.There are astm standards for sheet metal manufacturers that define the mechanical and physical properties limits for product coming from a rolling mill - where your sheet metal is coming from. From Working in a sheet metal penny for past 10 years I'd say . 5mm over 200mm flatness will be difficulty to achieve unless you have a specially agreed .

sheet metal gusset design guidelines

for sheet metal bending. In this paper, tolerance verification for sheet metal bending is addressed by providing a complete method to investigate the actual sources of errors in sheet metal bending and the resulting dimensional errors. Firstly, the crucial factors influencing the dimensional accuracy of the product are analysed.Comprehensive resource of fabrication tolerances and dimensional variation guidelines for sheet metal manufacturing and fabrication. . & Bend Sizes Bend Types Frequently Asked Questions Sheet Metal Design Tech Tip Videos Tolerances for Dimensional Variance in Sheet Metal and Machined Parts. Overview. Protocase takes great care to manufacture . These tolerance constraints apply not only when attaching two sheet metal parts together, but also when attaching sheet metal to other components such as weldments, or plastic/structural foam skins. Therefore .

The tolerance specified by the engineer or designer tell the brake operator how much variation in the particular bend is allowable. Typically this information is located in the title block of a drawing. Angle tolerances are typically denoted by ±x.xx °.Sheet Metal Tolerances for Bending and Stamping. Both bending and stamping have their unique tolerances. Bending: Bending is the process of reshaping metal without removing material. Tolerances are affected by the type and properties of the bending machine. We have calibrated our modern bending machines for consistent bending angles.The parts quoted were two bend sheet metal channels with holes in the top for slugs to weld to. Two parts needed to align together but overall channel dimensions has a bit of forgiveness in fit. . Overall channel dimensions "fab tolerances" (1/16 tolerance if possible or +-0.01" if needed slightly tighter) That was the main thing for the .with a standard bend radius, sheet metal tolerances are required to open. For simple bent parts, Xometry can offer a +/- 0.010” (+/- 0.254mm) tolerance for dimensions across a single bend. The bend radius itself is constrained to a +/- 1.0° tolerance. Multiple Surface Single Surface Edge to Edge +/-0.005 A +/-0.005 +/-0.005

Master sheet metal tolerances with our guide. Explore key factors, material properties, and best practices for precision fabrication. Skip to content. [email protected]. Call Us Today! (+86) 188-2253-7569 . Sheet Metal Bending. Sheet metal bending is a forming technique that makes V, U or channel shapes by deforming metal around a . Table of Contents. 0.1 Let us calculate bend gains for you!; 1 Quick Recap: What’s a Sheet Metal Bend Gain?. 1.1 ASM Gets Real About the Journey of Your CAD Model; 2 Let Us Calculate Your Bend Allowances (or Deductions) for You!; 3 Sheet Metal Bend Gains Chart. 3.1 BEND GAINS CHART DOWNLOAD; 4 Sheet Metal Bend Gains FAQ. 4.0.1 What is a sheet .We offer welded assemblies, standard mill, edge breaking, and orbital-sanded surface finishes along with a number of additional sheet metal finishing options:. Seam, tack, and stitch welding Hardware insertion and riveting: Standard PEM sheet metal hardware; Powder coating: A variety of powder coat paint colors available in textured and non-textured finish, including RAL colors.

For example, the manufacturer recommends ISO 2768-mk for sheet metal parts and ISO 2768-fh for machined components. In the above example, “m” and “k” have defined the tolerance class. You can calculate the critical dimension tolerance using tolerance stack-up analysis. You can also use a tolerance stack-up calculator for this purpose. Sheet metal Tolerance Standrards, welding Tolerance Standards, General Tolerance Standards, IS 2102 Tolerance details . and the tolerance between the bend and the second feature. An example is shown below. +/- 0.015Hole (A) to Bend +/- 0.020Bend To Bend +/- 0.015Hole (B) to Bend +/- 0.040 Tolerance between A and B.Sheet Metal Guage Tolerances During the rolling process the rollers bow slightly, which results in the sheets being thinner on the edges. The tolerances in the table and attachments reflect current manufacturing practices and commercial standards and are not representative of the Manufacturer's Standard Gauge, which has no inherent tolerances.

sheet metal dimensioning standards

sheet metal design guidelines pdf

This instructables details how to MIG weld a box made out of old scrap metal. You will need: 1. Thin steel. I used 1/8" steel from a local scrap yard. The amount depends on the size of box .

sheet metal bend tolerances|sheet metal bending basics