bottom bending sheet metal Air forming is the most common method of forming used today in the production of precision sheet metal parts and is listed by all major press . Leviton STRUCTURED MEDIA Centers create the ideal central distribution point to manage your residential structured cabling network, boosting performance for wired and wireless networks. The enclosures support a wide range of building types and floor plans.

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

Bottom bending creates reliable, accurate bends in sheet metal. Where accuracy in bend angles is important and variation between different parts in a production run needs to be avoided, bottom bending is preferable.Bottom bending, or bottoming, is a press brake operation that forms an angle in sheet metal by enclosing the sheet between the punch and the die. WILA .

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending . Air forming is the most common method of forming used today in the production of precision sheet metal parts and is listed by all major press .Sheet metal bending is a highly effective process for producing parts. Learn more about sheet metal bending today!Bottom bending, also known as air bending, is a widely used technique in sheet metal fabrication where the material is bent by pressing it between a punch and a die. Unlike other bending .

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a .Bottom bending is the process of stamps the radius of the punch tip into the work piece. This differs from Coining, which puts the entire surface of the work piece under such tonnage that it begins to flow. when Bottom Bending the die angle . Bottoming, also known as bottom bending or bottom pressing, is a precise sheet metal bending technique where the metal sheet is pressed against the bottom of a die to achieve a specific angle. Unlike air bending, where the .

Bottom bending creates reliable, accurate bends in sheet metal. Where accuracy in bend angles is important and variation between different parts in a production run needs to be avoided, bottom bending is preferable.Bottom bending, or bottoming, is a press brake operation that forms an angle in sheet metal by enclosing the sheet between the punch and the die. WILA offers durable and high quality precision tooling for bottom bending with 90° angles.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

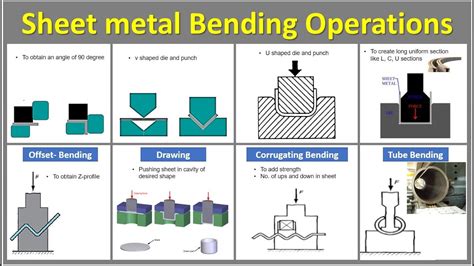

types of bending sheet metal

Air forming is the most common method of forming used today in the production of precision sheet metal parts and is listed by all major press brake manufacturers worldwide as the preferred method of sheet metal bending. Bottoming is also known as bottom pressing or bottom striking. As the name “bottom pressing” suggests, the punch presses the metal sheet onto the surface of the die, so the die’s angle determines the final angle of the workpiece. With bottoming, the inner radius of the angled sheet depends on the die’s radius.

Sheet metal bending is a highly effective process for producing parts. Learn more about sheet metal bending today!

Bottom bending, also known as air bending, is a widely used technique in sheet metal fabrication where the material is bent by pressing it between a punch and a die. Unlike other bending methods like coining or edge bending, bottom bending allows for greater flexibility, reduced setup time, and minimal risk of damaging the material.

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die).

Bottom bending is the process of stamps the radius of the punch tip into the work piece. This differs from Coining, which puts the entire surface of the work piece under such tonnage that it begins to flow. when Bottom Bending the die angle should match the intended angle of the work piece, adjusting a few degrees for Spring Back, hence the . Bottoming, also known as bottom bending or bottom pressing, is a precise sheet metal bending technique where the metal sheet is pressed against the bottom of a die to achieve a specific angle. Unlike air bending, where the metal doesn’t fully conform to the die, bottoming forces the metal to make full contact with the die’s surface. Bottom bending creates reliable, accurate bends in sheet metal. Where accuracy in bend angles is important and variation between different parts in a production run needs to be avoided, bottom bending is preferable.

Bottom bending, or bottoming, is a press brake operation that forms an angle in sheet metal by enclosing the sheet between the punch and the die. WILA offers durable and high quality precision tooling for bottom bending with 90° angles.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information. Air forming is the most common method of forming used today in the production of precision sheet metal parts and is listed by all major press brake manufacturers worldwide as the preferred method of sheet metal bending.

Bottoming is also known as bottom pressing or bottom striking. As the name “bottom pressing” suggests, the punch presses the metal sheet onto the surface of the die, so the die’s angle determines the final angle of the workpiece. With bottoming, the inner radius of the angled sheet depends on the die’s radius.Sheet metal bending is a highly effective process for producing parts. Learn more about sheet metal bending today!Bottom bending, also known as air bending, is a widely used technique in sheet metal fabrication where the material is bent by pressing it between a punch and a die. Unlike other bending methods like coining or edge bending, bottom bending allows for greater flexibility, reduced setup time, and minimal risk of damaging the material.

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die).Bottom bending is the process of stamps the radius of the punch tip into the work piece. This differs from Coining, which puts the entire surface of the work piece under such tonnage that it begins to flow. when Bottom Bending the die angle should match the intended angle of the work piece, adjusting a few degrees for Spring Back, hence the .

sheet metal bending standards

laser cutting sheet metal cost

laser metal sheet cutting machine manufacturer

laundry utility sink all-in-one cabinet stainless steel with faucet

sheet metal bending near me

By following proper installation guidelines, such as selecting the appropriate junction box size, securing cables with clamps or connectors, and ensuring the presence of a .

bottom bending sheet metal|bending galvanized sheet metal