hazmat associated with metal fabrication Metal Manufacturing and Fabrication. EPA adopted six national emphasis areas (NEAs) for the FY 2022/2023 pollution prevention (P2) grant cycle. This fact sheet summarizes environmental . Experience the retro-style 2D platformer VVVVVV, created by Terry Cavanagh.

0 · welding fabrication hazards

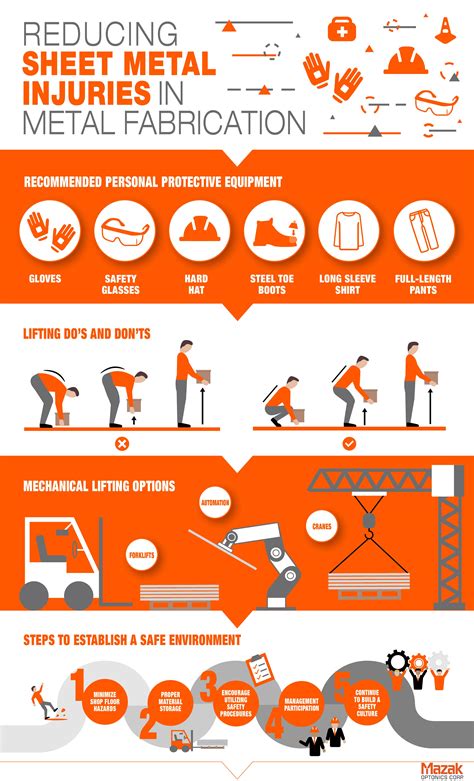

1 · sheet metal fabrication safety

2 · safety of metal fabrication

3 · metal fabrication safety standards

4 · metal fabrication safety requirements

5 · metal fabrication safety clothing

6 · metal fabrication hazards

7 · how dangerous is metal fabrication

A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

Health hazards from welding, cutting, and brazing operations include exposures to metal fumes and to ultraviolet (UV) radiation. Safety hazards from these operations include burns, eye . Learn everything about Metal Fabrication Safety for your metal shop big or small. Let's discuss precautions, hazards and safety rules when working with metal.Metal Manufacturing and Fabrication. EPA adopted six national emphasis areas (NEAs) for the FY 2022/2023 pollution prevention (P2) grant cycle. This fact sheet summarizes environmental . OSHA provides specific regulations and safety requirements for each of these toxic and hazardous substances. Metal fabrication companies must identify the types of toxic .

Exposures to hazards present in steel operations are addressed in specific OSHA standards for general industry. This section highlights OSHA standards and documents related to basic steel .Welding joins materials together by melting a metal work piece along with a filler metal to form a strong joint. The welding process produces visible smoke that contains harmful metal fume .

Some companies completely overlook sheet metal as a potential workplace hazard, leaving employees susceptible to work-related accidents. In this post, we're going to .This guide identifies some tasks undertaken in the metal fabrication manufacturing industry that are hazardous and have resulted in injuries. However it is not a comprehensive list of all tasks . If you’re looking to curb recurring incidents for your metal work and fabrication workers, here are four issues you should focus on. Lack of guards and other protection. The working environment in any metal fabrication plant has . Safety concerns in metal fabrication shops include hazardous materials, welding fumes, metals, chemicals, and more. Ventilation systems can help reduce toxic fumes. PPE like gloves, helmets, and aprons are also .

OSHA Standards: The Occupational Safety and Health Administration (OSHA) sets strict guidelines to protect workers from the dangers associated with hazardous materials. Our containers adhere to these standards by incorporating safety features such as explosion-proof accessories, mechanical ventilation, and fire suppression systems. 4. Metal fabrication Metal fabrication is a value added process that involves the construction of machines and structures from various raw materials. A fabrication shop will bid on a job, usually based on the engineering . In Section 3.1, the SERS substrates with four kinds of different designs were reviewed: metal nanoparticles (MNPs) in suspension, metal on solid substrates, metal on porous materials, and MNPs on biological or commercial substrates; in Section 3.2, the SERS substrates are separated into six kinds by the different fabrication processes: chemical .3.2 Protection Guidelines for Radiation and Hazardous Material Exposures 3-2 3.3 UF6 Shipping Containers and Sampling Tubes 3-3 3.4 Scrap Metal Pickup and Metal Recycling 3-4 3.5 Potential Long-Term Fate of UF6 3-4 4.0 Assessment Methodology 4-1 5.0 Results and Conclusions 5-1

The most effective way to minimize the losses associated with waste is to avoid producing the waste in the first place. . Replacing hazardous materials with less hazardous substitutes will reduce the toxicity of the waste. . Codes. Information relating to the metal fabrication industry is filed in the database under SIC codes 34 through 39 .

welding fabrication hazards

sheet metal fabrication safety

Last year citations from the Occupational Safety and Health Administration (OSHA) cost metal fabricating businesses more than million. The actual cost of these violations is much higher, however, because it does not include other direct or indirect costs such as damaged facilities or equipment, medical costs, replacement personnel, and increased workers’ .These classifications are based on the nature of the hazards and risks to building occupants generally associated with the intended purpose of the building or structure. . Group F (examples: metal or wood shop, photographic film development studio) High Hazard: Group H (examples: chemical storage room, flammable liquid dispensing room .

Category: Metal manufacturing and fabrication. Posted on September 20, 2024. Video resources for Pollution Prevention (P2) Week. In a previous post, we noted that September 16-20, 2024 is Pollution Prevention (P2) Week, and highlighted some relevant projects of the ISTC Technical Assistance Program (TAP). To conclude the week, we’ve compiled .

8 WORKSAFE VICTORIA / A GUIDE TO SAFETY IN THE METAL FABRICATION INDUSTRY MANUAL HANDLING UNLOADING RAW MATERIALS When unloading raw materials, incidents have occurred where people use levers, such as metal bars to manually lever steel and other metal products off delivery vehicles. This practice is known as ‘barring off’. By using purpose .The Journal of Hazardous Materials is an international forum that advances world class research by publishing articles in the areas of Environmental Science and Engineering. We publish full-length research papers, review articles, and perspectives that improve our understanding of the hazards and risks that certain materials pose to public health and the environment. Welding is a fabrication process involving combining two or more pieces of metal using heat and pressure. It is fundamental in various industries, including construction, manufacturing, automotive, and aerospace. . Taking these precautions can significantly reduce the risks associated with exposure to harmful welding fumes and gases. Remember .

For site-specific operations, such as repair garages or metal fabrication, permit length is 1 year. Citywide permits are for 1 year, but require the permit holder to conduct hot work operations at any individual location so long as such operation does not exceed 30 calendar days and all hazardous materials associated with such activity are .The handling of potentially hazardous materials without proper protection poses several risks to workers in the metal fabrication industry. These risks include: Skip to main content Skip to footer. Call 1300 877 609 to find out about the latest offers available. Store Home; SWMS Docs;Gained an awareness of security risks associated with hazardous materials transportation (HM-232) . from mining and petroleum refining to chemical manufacturing and metal fabrication. Even small businesses are capable of .

These injuries are commonly associated with manual labour, such as assembly line work or manual material handling in the metal fabrication industry. . such as overheating electrical malfunctions or hazardous . This includes labeling hazardous materials, providing safety data sheets, and conducting regular training sessions on hazard recognition and mitigation. Labeling Hazardous Materials. Proper labeling of hazardous .Secondly, safety is paramount in metal fabrication, and an SOP manual helps in outlining best practices for safe equipment operation, handling hazardous materials, and responding to emergencies. This minimizes workplace accidents and injuries, safeguarding the well-being of .

According to the U.S. Bureau of Labor Statistics, more than 16,000 workers are seriously hurt and 50 are killed every year in fabricated metal product manufacturing. From October 2022 to September 2023, OSHA issued .4 million in citations to metal fabrication facilities. OSHA has specific regulations for safe operations in metal fabrication .The Code of Federal Regulations (CFR) is the official legal print publication containing the codification of the general and permanent rules published in the Federal Register by the departments and agencies of the Federal Government. The Electronic Code of Federal Regulations (eCFR) is a continuously updated online version of the CFR. It is not an official . Of course, safety in the fabrication industry isn’t just about creating a positive culture; it also requires a deep understanding of the technical aspects of the work. As seasoned welders and fabricators, we’ve honed our skills in handling hazardous materials, operating heavy machinery, and navigating the complexities of confined spaces. Working with stainless steel can pose a greater threat to workers than other metals. A new rule aims to give workers more information about exposure to hexavalent chromium, a carcinogen released when stainless steel is welded, cut with a plasma torch or cast. The federal Occupational Safety and Health Administration changed its notification requirements in.

The expansion of industrial facilities for fabrication purposes can lead to habitat destruction. It can displace native flora and fauna, disrupt the ecosystem, and reduce biodiversity. Also, contaminated land can remain unusable for an extended period. The fabrication processes usually involve using hazardous materials like heavy metals and .

Sigma Technik Limited, as a prototype production company and rapid manufacturer focusing on rapid prototyping and low volume production of plastic and metal parts, has advanced manufacturing technology, one-stop service, diversified manufacturing methods, on-demand manufacturing services and efficient manufacturing processes, which can provide customers .The metal fabrication process involves dealing with raw, rough and rugged metal components which are then cut, bent, welded and assembled to form desired metal structures. The main involvement of complex, engaging and intense steps like welding and cutting demands utmost safety precautions if the organization wants to keep their valuable .Metal fabricating. Here you'll find links to health and safety information and resources for work in metal fabricating. To reduce the potential for injury or disease, it's important to manage the risks and hazards in your workplace. See our resources to learn more about common risks and hazards in your industry, or follow the links to these related topics: Study with Quizlet and memorize flashcards containing terms like Are your responsibilities as a Technician-Level responder clear? You have been called to an incident at a factory involving six 55-gallon drums leaking hydrochloric acid. Identify Three Technician-Level responsibilities., As a hazardous materials Technician, you must be able to perform all of the .

safety of metal fabrication

1986 ford bronco sheet metal

If you are planning to use sheet metal screws in your next project, the following will help you understand how to use them correctly, as well as answer some of the questions you may have about using them instead of another type of screw you may be more familiar with.

hazmat associated with metal fabrication|how dangerous is metal fabrication