sheet metal box forming To fabricate a sheet metal box, you will need a sheet metal of your desired thickness, a metal shear or snips, a metal brake, a drill press or hand drill, a deburring tool, a tape measure, a square, and safety equipment such as . MAKERELE ABS Plastic Waterproof Dustproof Electrical Junction Box, Universal Electrical Project Enclosure White D2.76”×H1.96”inch (D70 x H50 mm)

0 · sheet metal layout drawings

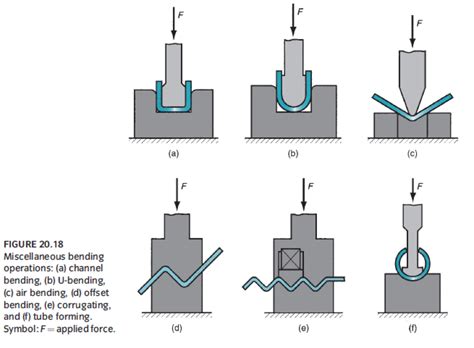

1 · sheet metal forming types

2 · sheet metal forming process pdf

3 · sheet metal forming press dies

4 · sheet metal forming pdf

5 · forming sheet metal by hand

6 · forming process in sheet metal

7 · bulk deformation vs sheet metal forming

A septic tank’s distribution box (or D-box) is a container (typically concrete) that receives the septic tank effluent and re-distributes it into the network of attached drain fields and pipes. To put it simply, its job is to evenly distribute the wastewater into the leach field.

In this Instructable I'm going to walk you through how to make one of these simple sheet metal boxes! If you are just beginning to work with sheet metal I recommend also checking out my . Fabricating a sheet metal box requires careful planning, precise cutting, skilled forming and bending, accurate joining, and meticulous finishing. The process involves transforming a flat metal sheet into a functional and . To fabricate a sheet metal box, you will need a sheet metal of your desired thickness, a metal shear or snips, a metal brake, a drill press or hand drill, a deburring tool, a tape measure, a square, and safety equipment such as .

Chap 2 , sheet metal – p. 1 Sheet Metal Forming Processes • involves workpieces with a high ratio of surface area to thickness • plates, thickness > ¼ inch • sheets, thickness ≤ ¼ inch • typical items produced by sheet-metal forming processes: metal desks appliance bodies . hubcaps aircraft panels . beverage cans car bodiesStudy with Quizlet and memorize flashcards containing terms like what should a sheet metal repair accomplish?, what is needed when control surface repairs alter the weight distribution?, what should a shop rivet look like when finished? and more. . how large are relief holes used in forming boxes? 2 times the bend radius. A sheet metal repair . Deep drawing and hydroforming are two different sheet metal forming processes. Deep drawing involves using a punch to form a sheet metal blank into a three-dimensional shape by pulling it into a die cavity. It is . CNC Press Brake Machine, Sheet Metal Bending Machine for bending box, cabinet#bendingmachine #pressbrake #cncpressbrake #electricpressbrake Factory Name:Wuxi.

Craftech Metal Forming has been serving the aerospace industry since 1996. Specializing in the use of drop hammers for sheet metal forming, Craftech strives to be a reliable source for quality aerospace parts to fit our customer's needs. We are AS9100D / ISO 9001:2015 3rd party certified, Nadcap approved (heat treatment; hardness / conductivity), and.

sheet metal layout drawings

Sep 10, 2024 - Explore Dejan Vračarević's board "METAL BOX" on Pinterest. See more ideas about metal box, sheet metal, metal.Air-Powered Sheet Metal Forming Hammers. These air-powered tools remove dents, smooth out ridges, and shape sheet metal more efficiently than manual hammers. Forming Spoons. Place against the face of your workpiece and strike with a hammer. The blow will transfer to the workpiece without damaging the finish.Avon Lake Sheet Metal has over 60 years of experience as a leader in Cleveland area sheet metal & structural steel fabrication services, construction & design. . High quality CNC sheet metal forming requires the use of a reliable and proven CNC laser and plasma cutting system that can produce consistent and precise results for some of the .Sheet Metal Forming 2.810 D. Cooper !“Sheet Metal Forming” Ch. 16 Kalpakjian !“Design for Sheetmetal Working”, Ch. 9 Boothroyd, Dewhurst and Knight . Examples-sheet metal formed . Female die Male die (punch/post) Metal sheet Blank holder (ring) on cushion Compressible

By varying the sheet metal-forming parameters, the rawmate-355 rial consumption can be optimized leading to cost reduction. 356 Under this study , weight of blank size for the component is 357

sheet metal forming types

The R-1600 Servo Driven machine is a fully Automated Trim, Bead & Flange machine. Programs can be loaded from CAD/CAM packages for complete design integrati.Critical Processes of Sheet Metal Forming. Sheet metal forming is a collection of critical processes that each serve a specific purpose in fabricating and assembling metal components. Here are some of the methods that we most commonly use at Shengen. Bending: It involves deforming metal around a straight line, creating a fold or bend. This is .

High precision is maintained by the proprietary build box design that reduces force distribution across the sheet during the build – a challenge that can impede accuracy, is difficult to predict, and has hindered other efforts to digitize sheet metal forming in the past. . Traditional sheet metal forming is a capital- and time-intensive .

Sheet metal boxes are versatile and functional, serving a variety of purposes across industries such as electronics, automotive, and HVAC. . Sheet Metal Fabrication is the process of forming metal sheets into structures or parts using various techniques such . The book gives a synthetic presentation of the research performed in the eld of sheet metal forming simulation during more than 20 years by the members of three international teams: the Research Centre on Sheet Metal Forming―CERTETA (Technical University of Cluj-Napoca, Romania); AutoForm Company from Zürich, Switzerland and VOLVO automotive .

The choice of material for custom sheet metal boxes is a crucial decision that impacts the box’s overall performance and longevity. Stainless steel, aluminum, and copper are commonly used materials due to their excellent . Sheet metal forming involves a process known as curling, in which sheet metal components are given smooth edges and cylindrical shapes by eliminating sharp edges or burrs. Curving provides extra safety due to its .Sheetmetal > Using Sheetmetal Design > To Create a Sheet Metal Part . To Create a Sheet Metal Part. 1. Click New. The New dialog box opens. 2. . For template-supported file types, if you always want to see the New File Options dialog box, set the force_new_file_options_dialog configuration option to Yes.

ip 68 junction box

Sheet Metal Bending is a pivotal process in the realm of sheet metal forming, crucial for shaping metal into desired angles and forms without compromising the material’s integrity. It utilizes force to manipulate metal around a single axis, yielding precise, clean bends along a predetermined bend line that are fundamental in manufacturing diverse products.Folding a Box - Sheet Metal Layout and Forming. A box can be formed the same way as the U-channel described on in the previous paragraphs, but when a sheet metal part has intersecting bend radii, it is necessary to remove material to make room for the material contained in the flanges. This is done by drilling or punching holes at the .

Forming involves clamping a piece of sheet metal between a top tool and a bottom die to create specified bends in the workpiece—an essential staple of the sheet metal manufacturing process. As part of our first-class equipment fleet, our Amada Astro II Robotic Press Brake allows production jobs to be set up and run as a lights-out operation .From bump forming to box forming and sanding. See what our team can do. Skip to content. Want to talk to a human? Our team is standing by! (603) 883 1510. . Bump Forming Sheet Metal Fabrication. AMADA 3kW Fiber Laser In Action! W Bend: Press Brake. Complex Forming Step 1. Complex Forming Step 4.This involves cutting, forming, and joining/assembling metal sheets. Various metals are used in this process, including steel, aluminum, stainless steel, brass, copper, and zinc. The thickness of sheet metal ranges from 0.15 to 6.25 mm (0.006 to 0.25 in.).

This kit includes 5 pancake dies which work together to form a 1" round lidded container. Use this pancake die set with 18-gauge sheet metal to create 1" round boxes with fitted lids! The kit includes pancake dies for two types of lids - over-fitted lids (lids that fit over the container), and inside-fitted lids (lids that have an inner rim that fits down into the container). These small .About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .Welcome to the comprehensive world of metal forming, where precision meets durability. This article delves into the essence of metal forming, unraveling its techniques, processes, and varied applications across industries.From the basic mechanics of metal deformation to the advanced equipment used, we cover the intricate details that define this manufacturing cornerstone.Storage boxes; Oilfield components; Custom components; CNC Sheet Metal Forming. CNC forming, when done correctly, can result in sheet metal fabrication for clients that allows for difficult curvatures in designs to look as if the metal was that shape from the start. We have decades of experience ensuring that multiple-radius forming matches the .

invacare bed junction box

sheet metal forming process pdf

Here's how 5-axis CNC machines are transforming manufacturing: 1. What is 5-Axis CNC Machining? Unlike traditional 3-axis systems, 5-axis machines move a part or tool along three linear axes (X, Y, Z) while rotating it along two additional axes (A, B). This capability allows manufacturers to approach the workpiece from virtually any angle .

sheet metal box forming|sheet metal forming process pdf