sheet metal creation process The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material . If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on either side of the box). You’ll also need to install cable clamps in the metal box. These thread into the box from the outside.

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal working process pdf

4 · sheet metal process pdf

5 · sheet metal process in manufacturing

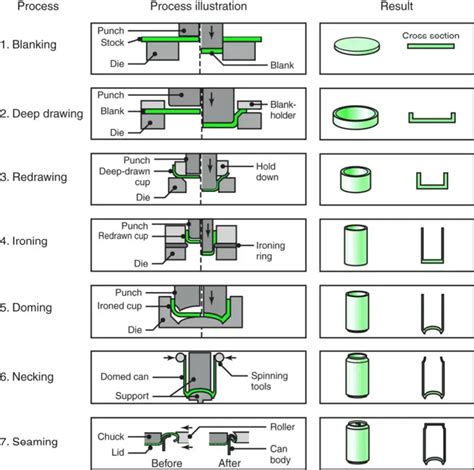

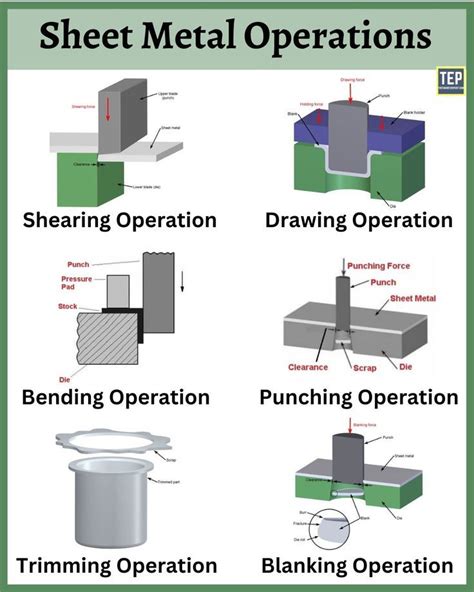

6 · sheet metal operations with diagrams

7 · sheet metal fabrication pdf

Welding sheet metal with TIG welding is very good when welding without filler wire, also called autogenous TIG Welding. TIG without filler requires less welding current compared to welding with filler and offers easy to join thin sheet metals easily.

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material . Sheet metal fabrication machines can be categorized into four main types: cutting machines, forming and bending machines, machining and drilling machines, and specialized machines. . These are just a few examples, and sheet metal fabrication is a versatile process with applications in numerous other industries. The efficiency and versatility .

how to remove standard handy wall electrical box

Fabrication of sheet metal is a manufacturing process that involves shaping and manipulating thin sheets of metal into desired parts and components. It typically includes cutting, bending, forming, and assembling metal sheets to . The sheet metal fabrication process consists of multiple steps to safely produce reliable products. Although specific steps may vary slightly, the overall process is the same. Step #1: Generate Blueprints. Products or pieces .Sheet metal forming encompasses a variety of techniques, each tailored to specific manufacturing needs, enabling the creation of detailed, complex shapes from flat metal sheets. Bending During this process, a piece of sheet metal is placed over a die and pressed into shape by a punch.

Sheet metal fabrication is a widely used manufacturing process that transforms flat sheets made from various metals, mainly steel, and aluminum, into functional shapes and structures. It does so by cutting, punching holes, and folding the metal sheets to achieve the.

how to remove metal electrical box from wall

Fabrication is not a single-shot process. It is a combination of different tools, processes, and techniques. So, manipulating a raw sheet into final shapes involves different sheet metal fabrication techniques, from cutting to joining.. Each fabrication technique serves a specific purpose in sheet metal parts manufacturing. Common Tolerancing Problems in Metal Fabrication. We frequently receive RFQs for parts with tolerances that exceed what is achievable in standard fabrication. Most of these issues are related to sheet metal forming, such as achieving ±0.005 tolerance across multiple bends, which surpasses our recommended default sheet metal tolerances.Additionally, we . Sheet metal fabrication is a process widely used in modern manufacturing due to its versatility, durability, and cost-effectiveness. It involves shaping and assembling sheet metals into various structures and components for the automotive, construction, aerospace, and consumer goods industries such as creating roofing and gutters. . Benefits of Precision Sheet Metal Fabrication Process. Precision sheet metal fabrication ensures that required standards yield high accuracy. Metals must fit precisely and high tolerance means that highly detailed metal parts are fashioned. Because state-of-the-art technology is exploited and as a result provides exact measurements to improve .

how to remove blue junction box from ceiling

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. . This sheet metal forming process is often used for vehicle body parts, enclosures, and electrical components. It can be performed on most compatible sheet metal forming materials, like stainless steel, brass, aluminum, and .

Metal fabrication is a process that is a big part of a lot of products and appliances that regular people use in their day-to-day life. This article attempts to present some basic information about metal fabrication, its different types, methods and so on. . Different stages of the sheet metal fabrication process. The Importance of Understanding Sheet Metal Fabrication Techniques. Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost optimization, and quality control. Sheet metal fabrication is the process of forming flat metal sheets into the desired parts and products by cutting, folding, bending, and assembling. There is an extensive range of metal materials that are suitable for various sheet metal fabrication processes, including steel, aluminum, stainless steel, brass, copper, and zinc.Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. Sheet metal is made from various materials, including steel, aluminum, zinc, and copper.

Sheet Metal Fabrication has become the need of the 21st century as every industry you name, whether it is aircraft, railway, plumbing, manufacturing, or any other requires sheet metal to build products that can .

Sheet metal fabrication is the process of shaping thin sheets of metal into useful structures and products. It involves taking flat sheet metal, cutting it into required shapes and sizes, and then bending it into the desired forms.

Sheet Metal Fabrication Process FMEA (PFMEA) example needed. Thread starter Sabrina Lim; Start date Sep 28, 2006; S. Sabrina Lim. Sep 28, 2006 #1 Hi, my client is asking for an example of pFMEA in sheet metal fabrication industry. Can anyone share an example or that of an industry where common processes include punching, laser cutting, stud . This sheet metal fabrication process can be used to bend large or small sheets of metal, and high-quality pieces can be fabricated quickly. CNC sheet bending can be used in the early stages of fabrication, or it can be used to adjust a finished or near-finished product. Dies are available for standard angles and operations, meaning custom .

various sheet metal processes

types of sheet metal process

This sheet metal fabrication process can be used to bend large or small sheets of metal, and high-quality pieces can be fabricated quickly. CNC sheet bending can be used in the early stages of fabrication, or it can be used to adjust a finished or near-finished product. Dies are available for standard angles and operations, meaning custom . Sheet metal fabrication is the main part of modern manufacturing. Most of the metal fabricated products are made of this process. For instance, take example of your home refrigerator; it has 0.7-1.0 mm thick steel sheets.

Sheet metal fabrication is a process that involves the creation of objects from thin sheets of metal. It can involve everything from simple shapes to more complex designs. In this article, we will discuss what sheet metal fabrication is, and provide a guide on how to design and manufacture products using this process.

types of sheet metal fabrication

In sheet metal fabrication, forming is an important process to transform flat metal materials into three-dimensional structures. According to different needs and design requirements, sheet metal forming can be divided into a variety of types, each method has its own unique characteristics and application scenarios.The term “sheet metal fabrication” describes the process of transforming flat metal sheets into metal products and structural designs. Most sheet metal processing techniques include converting various sheet metal types into components and parts by employing precision equipment like a CNC machine and several forming methods.Here’s a sheet metal fabrication guide covering metal types, capabilities and more! 262-251-1632; Contact Us; Careers; Industries; Renewable Energy Enclosures; . Through the fabrication process, those sheets are bent, formed and finished into kiosks, enclosures, cabinets more. Here are common sheet metal fabrication capabilities.

What Is Sheet Metal Fabrication? The sheet metal fabrication process takes many steps and requires a team to complete the process. We usually use steel, aluminum, stainless steel, and similar metals for manufacturing, as the industries that use our services need reliable products. Fabricating sheet metal involves stretching, cutting, and bending the metal to create the .

Sheet metal bending is a common and essential process in a sheet metal fabrication factory. This technique is the plastic deformation of a piece of metal along an axis, resulting in a change in the part’s geometry. Like other metal forming processes, bending alters the shape of the workpiece while maintaining the same volume of material. . 1. Rolling Metal. In the fabrication sector, rolling metal is among the most often used techniques. This procedure will be helpful particularly when dealing with sheet metal. Rolling reduces thickness by passing metal stock between two rollers, therefore guaranteeing consistency and strength. Large-scale projects like manufacturing steel beams .

how to remove rust from metal safe deposit box

how to replace a bt junction box

The Wireless CNC Adapter acts as an interface between any CNC control with an available RS232 or Ethernet port. The machine tool control can send from CNC memory to the Adapter, Adapter to CNC memory or drip-feed (DNC) from the Wireless CNC Adapter.

sheet metal creation process|types of sheet metal fabrication