about cnc lathe machine pdf A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and . Explore & source all the CNC replacement parts you need to keep your machine in top working order. Connect with us if you need help finding the correct part.

0 · cnc turning program examples PDF

1 · cnc turning machine programming PDF

2 · cnc turning cycle program PDF

3 · cnc programming for dummies PDF

4 · cnc programming PDF free download

5 · cnc machine parts list PDF

6 · cnc machine operation manual PDF

7 · cnc lathe manual PDF

Brass Pin Plated Gold Connector Specifications: Male Connector Size: .

cnc turning program examples PDF

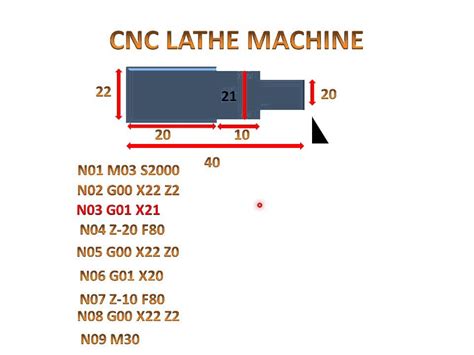

A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and .All CNC machines move tools to specific locations described by coordinate systems. With lathes the coordinate system can be simply described as two number lines that intersect.Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual .In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal .

Machine Types Lathe The engine lathe, one of the most productive machine tools, has always been an efficient means of producing round parts (Fig. 4). Most lathes are programmed on two .The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, .For a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting point is called a “program reference point”. The X axis assumes a spindle center line to be a position .

Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in . In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.All CNC machines move tools to specific locations described by coordinate systems. With lathes the coordinate system can be simply described as two number lines that intersect.

Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment. They may be incomplete or contain errors. Always abide by shop safety instructions and never engage in horseplay.In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability. The same principles used in operating a manual machine are used in programming a CNC machine.Machine Types Lathe The engine lathe, one of the most productive machine tools, has always been an efficient means of producing round parts (Fig. 4). Most lathes are programmed on two axes. •The X axis controls the cross motion of the cutting tool. Negative X (X-) moves the tool towards the spindle

The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machine, tube bending machine etc. HighlyFor a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting point is called a “program reference point”. The X axis assumes a spindle center line to be a position of “XO”, and the Z axis assumes a workpiece finish end face .

This file is the Adobe Acrobat version of Denford G and M Programming for CNC Lathes. File Optimisation: On-screen display and printing. Graphics: resampled to 600 dpi. Lan guage: European English. Paper size: A4 (210mm x 297mm). Denford Customer Services. Tel: +44 (0) 1484 722733. e-mail: customer_services @denford.co.uk.

Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.

A computerized numerical control (CNC) machine controls the tool with a computer and is programmed with a machine code system that enables it to operate with repeatability and minimal supervision. The same principles used in operating a manual machine are used in .

In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.All CNC machines move tools to specific locations described by coordinate systems. With lathes the coordinate system can be simply described as two number lines that intersect.Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment. They may be incomplete or contain errors. Always abide by shop safety instructions and never engage in horseplay.In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability. The same principles used in operating a manual machine are used in programming a CNC machine.

Machine Types Lathe The engine lathe, one of the most productive machine tools, has always been an efficient means of producing round parts (Fig. 4). Most lathes are programmed on two axes. •The X axis controls the cross motion of the cutting tool. Negative X (X-) moves the tool towards the spindle

cnc turning machine programming PDF

The applications of CNC include both for machine tool as well as non-machine tool areas. In the machine tool category, CNC is widely used for lathe, drill press, milling machine, grinding unit, laser, sheet-metal press working machine, tube bending machine etc. HighlyFor a CNC lathe, coordinate axes X and Z are set on the machine and their intersecting point is called a “program reference point”. The X axis assumes a spindle center line to be a position of “XO”, and the Z axis assumes a workpiece finish end face .

24x 24 sheet metal

Founded in 2006, as China CNC Machining Parts Manufacturer , MaiJin is specialized in all various custom-made CNC machining parts and CNC milling parts as well as Precision Turned Parts, Spacers etc.

about cnc lathe machine pdf|cnc programming PDF free download