minimum bend radius sheet metal The Basics of Bend Radii in Sheet Metal. Sheet Metal Bend Radius Guidelines. Here are a few key concepts to know about designing for sheet metal. Brackets, covers, cabinets, chassis, electrical enclosures.

What is a Spider Box? A spider box is a mobile power distribution panel that uses a single-phase, 250 VAC power source to distribute electricity economically.

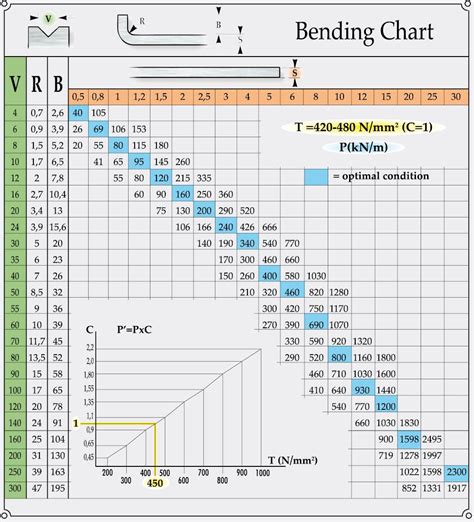

0 · sheet metal bending chart

1 · sheet metal bend deduction chart

2 · minimum sheet metal hamtramck radius

3 · maximum thickness sheet metal bending

4 · bend radius chart sheet metal

5 · aluminum minimum bend radius chart

6 · 304 stainless steel bend radius

7 · 304 stainless minimum bend radius

The extra length that we need to add to the total length of the legs of the finished component, in order to get the length of the flat pattern, is called the Bend Allowance. And, Bend Allowance is always equal to the length of the arc of the bend, measured along the neutral axis.

A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. For example, if the thickness of the sheet is 2mm, the minimum bend radius .The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications. Since commercial sheet metal bending can be done with less concern for .

The minimum recommended ratio is 1:6 and bending with a ratio of less than 1:4 is not recommended. Suggestion: If the strength allows, it is preferable to groove first and then bend in order to achieve a small sheet . In steel between 0.5 and 0.8 in. thick, grade 350 and 400 may have a minimum bend radius of 2.5 times the material thickness when transverse bending, while longitudinal bending may require a minimum bend radius that’s . To ensure the bending strength of the sheet metal, the bending radius should be greater than the minimum bending radius specified for that particular sheet metal material. The minimum bending radii for various .The Basics of Bend Radii in Sheet Metal. Sheet Metal Bend Radius Guidelines. Here are a few key concepts to know about designing for sheet metal. Brackets, covers, cabinets, chassis, electrical enclosures.

RECOMMENDED MINIMUM BEND RADII FOR 90-DEGREE COLD FORMING OF SHEET The radii listed are the minimum recommended for bending sheets and plates without fracturing in . We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, . If your sheet metal manufacturing designs has bends, follow the following design rules. 1. Maintain a uniform bend radius, the minimum radius at which a material can be bent .

The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. A typical recommendation is 1t for all sheet metal parts, which .We go beyond the general rules of sheet metal bending, as our customers want tight bend radii for sheet metal parts. It is possible to choose other bends if you require, but additional . Includes Minimum Closeness of Cutout to Bend Radius Cold Rolled Steel – 14 gauge ( 0.075” | 1.91mm ) 0.415” 0.07” Cold Rolled Steel – 16 gauge ( 0. . We recommend a minimum bend radius of 1t for all sheet metal parts. Thus the smallest radius of any bend in a sheet should be at least equal to the thickness of the sheet. For example, if the thickness of the sheet is 1 mm, . IV. Press Brake Bend Radius Calculation. The 8 times rule is a general guideline for determining the V-shaped die opening, suggesting that the V-die opening should be 8 times the material thickness. However, there is no exact formula for determining the ideal bend radius for sheet metal, but under certain specified force conditions, the bend radius can be estimated .

The bend radius refers to the minimum radius that a metal sheet can be bent without causing any damage or deformation. It is important because it helps determine the required bending force, the quality of the bend, and the overall structural integrity of the metal part.The bend radius is a critical parameter in sheet metal fabrication, dictating the minimum radius one can bend a metal sheet without significant deformations. Calculating the correct bend radius is essential for ensuring the structural integrity and aesthetic of the finished product. Calculating Bend Radius in Air Forming

Bending Radius Bending Radius refers to the minimum radius that can be applied to a sheet metal component where its flange originates from. Bending radii are usually dictated by available tooling, and for quick and effective design work it is recommended to speak with manufacturers so that design can be done around their standard operating procedures as well as available tooling. The minimum sheet metal bending height should be calculated as 2 times the thickness of the sheet metal plus the bending radius, i.e., H ≥ 2t + R. As illustrated in the accompanying figure, if the bending height is too low, the sheet metal is prone to deformation and twisting during the bending process , leading to suboptimal part shape and . Generally, sheet metal refers to metal materials with uniform thickness. Common sheet metal materials include stainless steel, galvanized steel, tinplate, copper, aluminum, and iron. This article primarily analyzes the basic principles of sheet metal product design. 1. Minimum Bending Radius for Sheet Parts The minimum bend radius varies depending on the material properties, particularly its ductility and work hardening characteristics. Here are some guidelines for common materials used in metal fabrication: . Imagine bending sheet metal without leaving a single mark or scratch. In this article, we explore innovative techniques for mark-free .

The bend’s outer edge would crack if it exceeds the minimum bend radius which is typically specified according to the metal sheet thickness (t) like 1t, 2t, 3t etc. A typical recommendation is 1t for all sheet metal parts, which means the smallest bend radius should be at least equal to the sheet thickness. Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at .Bend Radius - As a rule, inside bend radius should be equal to material thickness. When the . Form height to thickness ratio – To determine the minimum form height for sheet metal use the following formula: D = 2.5T + R (see below) The height can be less but it required secondary

15000 mw blue cnc universal laser engraving machine reviews

Here you can specify many of the sheet metal specific properties including bend radius, K-factor, and bend relief dimensions. These can be fixed values or formulas based on the material thickness. (Note: you can find all of this information for your chosen material and thickness in our bending calculator as well.)

sheet metal bending chart

Here you can specify many of the sheet metal specific properties including bend radius, K-factor, and bend relief dimensions. These can be fixed values or formulas based on the material thickness. (Note: you can find all of .

Sheet Metal Bending Radius refers to the minimum radius that can be applied to a sheet metal component where its flange originates from. Bending radii are usually dictated by available tooling, and for quick and effective .Assuming you used an inside bend radius smaller than the material thickness, the K-factor (or neutral factor, if you prefer) in our cheesy example would be 0.33 for an air bend and 0.42 for a bottom bend, both gradually increasing to 0.5 for . An overview of bend radius for sheet metal, including types, materials, tools, and important design considerations is provided in this article. +1(213) 398 9420 . A general rule of thumb for bending sheet metal is that the minimum bend radius should be equal to the material thickness of mild steel, 1.5 times the material thickness of .

14 x 3 4 sheet metal screw

The minimum bend radius is affected by; the kind of material, _____ of the material, and _____ condition of the material. Thickness Temper. The minimum radius of bend is specified for each type of aircraft sheet metal T or F. T. If the radius of the bend is too small. It weaken the metal and may crack. The radius of the bend is measured on.Minimum inside bend Radius for Sheet Metal Parts Recommended inside bend radius for sheet metal parts should be equal to material thickness. For hard materials (Stainless steel, CRCA), an inside bend radius equal to 0.65 times of sheet thickness is also enough. Learn the 20 percent rule to better predict the sheet metal inside bend radius when air forming during your welds, and find our sheet metal bend radius chart here. Our Sites . FMA; The Fabricator; FABTECH; . This chart shows a minimum bend radius of 0 to 1 times the material thickness for 0.125-in.-thick 5052-H32. This is slightly different . While sheet metal gauges run from 0.005 to 0.249 inch thick, aluminum and steel plate thicknesses start at 0.250 in. and go all the way up to 13 in. or even more. Likewise, . Finding the true minimum bend radius for steel or aluminum plate requires a little research. This should include data from your material supplier, whether you are .

Commercial sheet metal radius are created with less concern for stresses created during forming and radii can approach zero (sharp internal corner) for many thin sheet metal gages. . better parts and ultimately designs. ALUMINUM (BARE & CLAD) Minimum Bend Radii Note: Bend radius of zero is achievable for .012 - .050 material thickness .On the slip roll, the floor rollers _____ or grip the metal sheet while the rear roll provides the proper _____ to the work. feed; curvature. It is advantageous to _____ or even polish the edges of a flange that must undergo even moderate _____ to avoid crack formation . The minimum bend radius is affected by; the kind of material, _____ of .Bend Radius. Sheet metal bend brakes are used to bend material into the parts desired geometry. Bends that are in the same plane need to be designed in the same direction to avoid part re orientation, to save both money and time. . Sheet metal parts with a minimum of 0.9mm to 20mm in thickness can be manufactured. Hole Diameter. When .This article aims to provide a comprehensive guide to Minimum Bend Radius in sheet metal, using specific parameters and data to help clients grasp the importance and implications of this concept. Material Type Minimum Bend Radius (mm) Material Thickness (mm) Bend Angle (°) Bend Allowance Y-Factor K-Factor; Mild Steel: 1.0: 1.0: 90: 0.5:

How to calculate tonnage, internal radius and other bend parameters. This tool allows you to determine tonnage, internal radius, V-die opening and minimum flange.You just have to insert the characteristics of the sheet metal to be bent.

sheet metal bend deduction chart

The key difference is that the main panel is the breaker box where the electrical power from the electrical company flows through and controls the power supply to the entire building, while a sub-panel installation is a secondary breaker box that distributes power to specific areas or circuits within the building, and has its own breakers.

minimum bend radius sheet metal|aluminum minimum bend radius chart