cnc machine bed design Design Factors of the CNC Machine Bed The design of the CNC machine bed is an essential factor that determines the machine's rigidity,accuracy,and overall machining capacity. Let–s . Most ceiling fan boxes require 10 screws. However, some ceiling fan boxes require 8 screws. It is important to use the correct size screws for your ceiling fan box, as using the wrong size screws could damage the ceiling fan box or the ceiling.

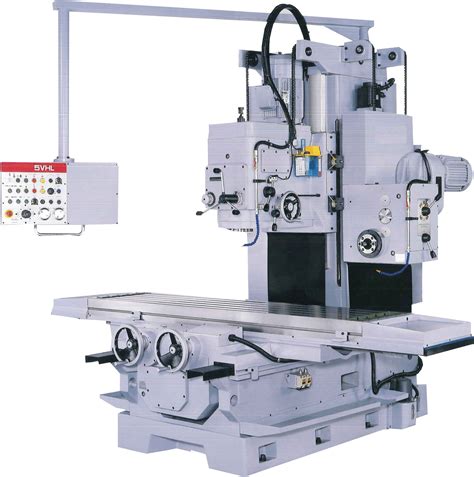

0 · milling machine bed

1 · long bed cnc milling machine

2 · fixed bed milling machine

3 · cnc machine bed

4 · cnc bed mill

5 · cnc bed design

6 · bed mill cnc for sale

7 · 2d bed design cnc

Whether you're a hobbyist looking to turn your passion into profit or an entrepreneur searching for CNC projects that sell, this guide is your gateway to the world of CNC design ideas. 1. .

milling machine bed

Understanding the CNC Machine Bed. The machine bed is the structural backbone of a CNC machine. It supports all other components, including the spindle, tool changer, and .Learn about how the many different kinds of CNC machines work, the materials available, the benefits & limitations, basic design rules and the most common applications.The incorporation of sensor technology in CNC machine bed design enables real-time monitoring and adjustments during machining processes. Sensors can measure vibrations, temperature, .

The MSE sensitivity method is introduced to optimise the structure size of the lathe bed, improve the design efficiency, reduce the test cost, then improve the performance of the machine. It has important theoretical and .

long bed cnc milling machine

fixed bed milling machine

Design Factors of the CNC Machine Bed The design of the CNC machine bed is an essential factor that determines the machine's rigidity,accuracy,and overall machining capacity. Let–s .CNC DXF and RLF are file formats commonly used in CNC machining. DXF is a widely supported vector format, while RLF is specific to ArtCAM software for 3D relief carving. DownloadIn this article, MGX200 CNC lathe pad selected for the whole static and vibration investigation. The test effort finished to scale back the solidity of pad without spoil its easy inflexibility and .

In a slant bed CNC lathe, the bed is angled or slanted, typically at around a 30 to 45-degree angle. This design allows for better chip evacuation, as gravity helps to remove chips from the work area. It also provides enhanced .

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! Understanding the CNC Machine Bed. The machine bed is the structural backbone of a CNC machine. It supports all other components, including the spindle, tool changer, and worktable. A robust machine bed ensures stability, reduces vibrations, and contributes to the overall accuracy and longevity of the machine. Historical Evolution of Machine BedsIn this article, I discuss the ins and outs of the two main bed designs for CNC lathe machines: the true slant bed and the flatbed “flying wedge” configurations.

Learn about how the many different kinds of CNC machines work, the materials available, the benefits & limitations, basic design rules and the most common applications.The incorporation of sensor technology in CNC machine bed design enables real-time monitoring and adjustments during machining processes. Sensors can measure vibrations, temperature, and other relevant parameters, allowing for proactive maintenance and optimization.

stainless steel lunch box in homecare

The MSE sensitivity method is introduced to optimise the structure size of the lathe bed, improve the design efficiency, reduce the test cost, then improve the performance of the machine. It has important theoretical and practical significance to improve the design level of CNC pipe thread lathe.

Design Factors of the CNC Machine Bed The design of the CNC machine bed is an essential factor that determines the machine's rigidity,accuracy,and overall machining capacity. Let–s delve into a few aspects.CNC DXF and RLF are file formats commonly used in CNC machining. DXF is a widely supported vector format, while RLF is specific to ArtCAM software for 3D relief carving. DownloadIn this article, MGX200 CNC lathe pad selected for the whole static and vibration investigation. The test effort finished to scale back the solidity of pad without spoil its easy inflexibility and therefore the exactness of the device through body process material. In a slant bed CNC lathe, the bed is angled or slanted, typically at around a 30 to 45-degree angle. This design allows for better chip evacuation, as gravity helps to remove chips from the work area. It also provides enhanced rigidity and .

The GrabCAD Library offers millions of free CAD designs, CAD files, and 3D models. Join the GrabCAD Community today to gain access and download! Understanding the CNC Machine Bed. The machine bed is the structural backbone of a CNC machine. It supports all other components, including the spindle, tool changer, and worktable. A robust machine bed ensures stability, reduces vibrations, and contributes to the overall accuracy and longevity of the machine. Historical Evolution of Machine Beds

In this article, I discuss the ins and outs of the two main bed designs for CNC lathe machines: the true slant bed and the flatbed “flying wedge” configurations.Learn about how the many different kinds of CNC machines work, the materials available, the benefits & limitations, basic design rules and the most common applications.The incorporation of sensor technology in CNC machine bed design enables real-time monitoring and adjustments during machining processes. Sensors can measure vibrations, temperature, and other relevant parameters, allowing for proactive maintenance and optimization.

The MSE sensitivity method is introduced to optimise the structure size of the lathe bed, improve the design efficiency, reduce the test cost, then improve the performance of the machine. It has important theoretical and practical significance to improve the design level of CNC pipe thread lathe.

Design Factors of the CNC Machine Bed The design of the CNC machine bed is an essential factor that determines the machine's rigidity,accuracy,and overall machining capacity. Let–s delve into a few aspects.

CNC DXF and RLF are file formats commonly used in CNC machining. DXF is a widely supported vector format, while RLF is specific to ArtCAM software for 3D relief carving. DownloadIn this article, MGX200 CNC lathe pad selected for the whole static and vibration investigation. The test effort finished to scale back the solidity of pad without spoil its easy inflexibility and therefore the exactness of the device through body process material.

In a slant bed CNC lathe, the bed is angled or slanted, typically at around a 30 to 45-degree angle. This design allows for better chip evacuation, as gravity helps to remove chips from the work area. It also provides enhanced rigidity and .

cnc machine bed

chart to figure out which size box matches or exceeds those requirements. If you go with a nonmetallic box, the size is usually stamped di-rectly on the box (bottom photo, facing page). Nonmetallic boxes are inexpensive and easy to install—Nonmetallic boxes have be-come the most commonly used boxes for resi-dential applications.

cnc machine bed design|long bed cnc milling machine