best flux core welding wire for sheet metal $65.90 The National Electrical Code has published a chart that determines a junction box’s correct size, based on the number and size of the conductors it must accommodate. The size of a conductor is expressed as AWG (American .

0 · mig flux core welding wire

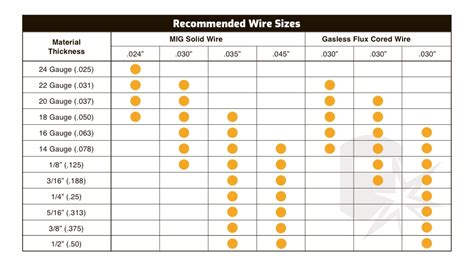

1 · flux cored wire classification

2 · flux core wire size chart

3 · flux core welding wire types

4 · flux core welding thin metal

5 · best mig flux core wire

6 · best flux core wire size

7 · best 030 flux core wire

With the advent of technology in Metal Fabrication, lots of machinery is available that helps the fabricators in their tasks as well as enhances their workflow. The benefits of using metal fabrication machinery do not end here.

Gasless flux core wire is used to generate its own shielding gas for a weld. This prevents impurities from contaminating the weld and because there’s no need for gas – it makes for a more portable welding solution than standard solid wire welding might. This approach to welding is also valuable in windy, . See more

Yes, it’s fine to use flux core wire in a MIG welder and there’s no need to buy a separate flux core welder. As I touched on previously, this can . See moreNo. Though you may find some chancers on the Internet selling “flux cored aluminum wire” when you read the small print – you’ll find that it says “we . See more Blue Demon E71T-GS .035 Flux Core Wire is a self-shielded mild steel wire suitable for both carbon and manganese steels. It’s able to do both single pass and multiple ..90

Is there a good flux core wire that stays stable and is better for welding thin material? I saw that Lincoln and Hobart are well-regarded, but is that because they get good penetration and burn hot and thus would not be useful . ‘Blue Demon E71TGS’ stays on top as the best flux core wires for sheet metal and in the .035-inch category. ‘Forney 42300 E71TGS’ makes the strongest case as the top .030 ..99.69

.99.79.99INETUB BA71TGS .030-Inch is one of the best flux core wire that is highly recommended as a self shielding wire. It works great on carbon and carbon-manganese steel. This Italian .

This flux core wire is a 0.35-inch diameter wire capable of welding up to a 5/16-inch thick plate with the best penetration. The wire is designed to be used on galvanized, coated, rusty, or painted metal with the best outcomes. Read on to discover why these wires are the top picks. And choose the perfect one for you and your key welding projects. 1. INE INETUB BA71TGS Mild Steel Flux Cored Wire .

0.99.47.236.62

mig flux core welding wire

.23 Flux-Cored Wire. Using “cored” wire allows a MIG welder to skip the tank of CO2 or argon and weld without the gas. That’s because the wire core contains ingredients that do the job of shielding the weld pool. Like stick rod . Blue Demon E71TGS might be the best flux core welding wire for home users and hobbyists. It’s very much aimed at this section of the market and runs well even with a 110V welding machine. You won’t have issues welding galvanized steel with this wire as many welders report positive results.

Blue Demon E71T-GS .035 Flux Core Wire is a self-shielded mild steel wire suitable for both carbon and manganese steels. It’s able to do both single pass and multiple pass welding. It’s good for jobs like sheet metal stitch welding or .

Is there a good flux core wire that stays stable and is better for welding thin material? I saw that Lincoln and Hobart are well-regarded, but is that because they get good penetration and burn hot and thus would not be useful for my particular problem.Are you looking for the best flux core wire for sheet metal? If so, you have come to the right place. A flux cored wire is soft and malleable, meaning that it can be easily bent and molded into complex shapes without breaking or buckling. ‘Blue Demon E71TGS’ stays on top as the best flux core wires for sheet metal and in the .035-inch category. ‘Forney 42300 E71TGS’ makes the strongest case as the top .030-inch wire and the best flux core wire for mild steel.INETUB BA71TGS .030-Inch is one of the best flux core wire that is highly recommended as a self shielding wire. It works great on carbon and carbon-manganese steel. This Italian manufactured wire is reputed for its versatility.

This flux core wire is a 0.35-inch diameter wire capable of welding up to a 5/16-inch thick plate with the best penetration. The wire is designed to be used on galvanized, coated, rusty, or painted metal with the best outcomes. Read on to discover why these wires are the top picks. And choose the perfect one for you and your key welding projects. 1. INE INETUB BA71TGS Mild Steel Flux Cored Wire Insiders View. 2. Blue Demon E71TGS Mild Steel Flux Cored Wire Insiders View. 3. Lincoln Electric Inner Shield NR-211-MP Mild Steel Flux Cored Wire Insiders View. 4.

cnc machine maintenance contract

Flux-Cored Wire. Using “cored” wire allows a MIG welder to skip the tank of CO2 or argon and weld without the gas. That’s because the wire core contains ingredients that do the job of shielding the weld pool. Like stick rod coatings, the core of the wire contains a flux agent that substitutes for the tank of shielding gas.

Welding thin sheet metal with flux core is a great way to produce complex, detailed shapes quickly and efficiently. In this article, you will learn about flux core welding and get tips for successfully using. Blue Demon E71TGS might be the best flux core welding wire for home users and hobbyists. It’s very much aimed at this section of the market and runs well even with a 110V welding machine. You won’t have issues welding galvanized steel with this wire as many welders report positive results.

Blue Demon E71T-GS .035 Flux Core Wire is a self-shielded mild steel wire suitable for both carbon and manganese steels. It’s able to do both single pass and multiple pass welding. It’s good for jobs like sheet metal stitch welding or . Is there a good flux core wire that stays stable and is better for welding thin material? I saw that Lincoln and Hobart are well-regarded, but is that because they get good penetration and burn hot and thus would not be useful for my particular problem.Are you looking for the best flux core wire for sheet metal? If so, you have come to the right place. A flux cored wire is soft and malleable, meaning that it can be easily bent and molded into complex shapes without breaking or buckling. ‘Blue Demon E71TGS’ stays on top as the best flux core wires for sheet metal and in the .035-inch category. ‘Forney 42300 E71TGS’ makes the strongest case as the top .030-inch wire and the best flux core wire for mild steel.

INETUB BA71TGS .030-Inch is one of the best flux core wire that is highly recommended as a self shielding wire. It works great on carbon and carbon-manganese steel. This Italian manufactured wire is reputed for its versatility.

This flux core wire is a 0.35-inch diameter wire capable of welding up to a 5/16-inch thick plate with the best penetration. The wire is designed to be used on galvanized, coated, rusty, or painted metal with the best outcomes. Read on to discover why these wires are the top picks. And choose the perfect one for you and your key welding projects. 1. INE INETUB BA71TGS Mild Steel Flux Cored Wire Insiders View. 2. Blue Demon E71TGS Mild Steel Flux Cored Wire Insiders View. 3. Lincoln Electric Inner Shield NR-211-MP Mild Steel Flux Cored Wire Insiders View. 4.

Flux-Cored Wire. Using “cored” wire allows a MIG welder to skip the tank of CO2 or argon and weld without the gas. That’s because the wire core contains ingredients that do the job of shielding the weld pool. Like stick rod coatings, the core of the wire contains a flux agent that substitutes for the tank of shielding gas.

Consumer metal products are items used in everyday life, such as cutlery, kitchen appliances, tools, and furniture. These products are often made from stainless steel, .

best flux core welding wire for sheet metal|best flux core wire size