forming metal sheet Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different . G-code (also RS-274) is the most widely used computer numerical control (CNC) and 3D printing programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, as well as for 3D-printer slicer applications. The G stands for geometry. G-code has many variants.

0 · sheet metal layout drawings

1 · sheet metal forming types

2 · sheet metal forming process pdf

3 · sheet metal forming press dies

4 · sheet metal forming pdf

5 · forming sheet metal by hand

6 · forming process in sheet metal

7 · bulk deformation vs sheet metal forming

We discussed the various types of electrical box screws, including machine screws, self-tapping screws, wood screws, drywall screws, and anchor screws. We also provided insights into the recommended screw sizes for different box types, such as outlet boxes, switch boxes, junction boxes, and ceiling boxes.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different .From metal cans to protective housing for hardware, parts created by sheet metal forming are found everywhere in our daily lives. In this article, learn the basics of sheet metals, the various sheet metal forming processes, and how to reduce .

Sheet metal machines are widely used in various manufacturing industries for shaping, cutting, and forming sheet metal into different components. Some of the industries that extensively utilize sheet metal machines include light industries such as electrical and medical equipment, all the way up to heavy industries such as automotive, rail, oil and gas, as well as .The best in sheet metal forming equipment, along with highly skilled software technicians and experienced metal forming fabricators allow us to move your parts from order to completion in days. And WE GUARANTEE IT! You’ll .

Chap 2 , sheet metal – p. 1 Sheet Metal Forming Processes • involves workpieces with a high ratio of surface area to thickness • plates, thickness > ¼ inch • sheets, thickness ≤ ¼ inch • typical items produced by sheet-metal forming processes: metal desks appliance bodies . hubcaps aircraft panels . beverage cans car bodiesSheet Metal Folding Tool: Hurricane 18" sheet metal folding tools offer a premium choice for bending and forming metal, folding seams are formed from two steel halves, permanently joined together Two Folding Depths: Creates 3/8" and 1" depth folding in ductworkIn metalworking, forming is the fashioning of metal parts and objects through mechanical deformation; the workpiece is reshaped without adding or removing material, and its mass remains unchanged. [1] Forming operates on the materials science principle of plastic deformation, where the physical shape of a material is permanently deformed.The FluidForming sheet metal forming process accommodates integrated logos, undercuts, organic forms, deep drawn parts, and even components with curves that would be likely to wrinkle or tear with traditional metal forming methods. FluidForming sheet metal forming is designed for low- to medium-volume parts production.

Sheet Metal Forming and Slide Forming Department Valco Valley Tool & Die is your global source for metal parts manufacturing in Cleveland, Ohio. Recognized for our upstanding reputation for quality products, services, and performance, our manufacturing facility can meet the metal forming needs of your business, whatever they might be.

Sheet metal expanding is a specialized process within sheet metal forming that involves stretching the metal to create a mesh-like pattern. This technique enhances the flexibility and strength of the sheet metal, making it suitable for various applications, including filtration, screening, and architectural details.

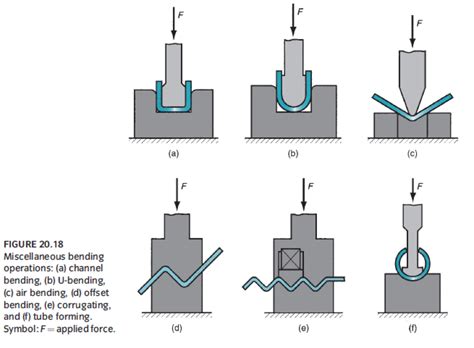

Louver in Sheet metal Automobile manufacturers. Originally called louvers cut holes in the engine of the motor to cool the engine. Louvers can be done with a sheet metal nibbling machines and then stop dead at the same louver forms and cut sheet metal as they press through it.Many companies, particularly in the aerospace market, use Flexform™ to form the majority of their sheet metal production parts. Fluid cell forming is perfectly suited to the relatively low-volume requirements of commercial, military and business aircraft.Sheet metal forming processes are those in which force is applied to a piece of sheet metal to modify its geometry rather than remove any material. The applied force stresses the metal beyond its yield strength, causing the material to plastically deform, but not to fail. By doing so, the sheet can be bent or stretched into a variety of complex shapes.What are the types of metal forming processes? Bending; Stretching; Deep Drawing; Roll Forming; Extrusion; Punching; Stamping; Ironing; Hydroforming; Metal forming is a part of the metal fabrication process and is used to create structural parts or complex pieces out of metal sheets and tubing. It’s an essential procedure for a wide variety of products — without it, our .

The forming analysis system ARGUS supports the optimization of the sheet metal forming process. For the automatic optical forming analysis, sheet metal blanks are marked with a regular dot pattern with 1 mm, 2 mm or 3 mm distance in between the dots, depending on the shape and radians of the part.Custom Sheet Metal Forming, Water-Jet Cutting, and On-Site Roll Forming. Architectural Metal Specialists (AMS) has been serving the Architects and Building Contractors throughout the Midwest since 1997 with custom .Sheet metal forming is one of the most important manufacturing processes. This is particularly valid for the automotive industry where sheet metal forming has an even more important key position. The automotive industry is the leading . Forming The sheet metal shaping has been accomplished for thousands of years (and it is carried out still nowadays!) through the hammering technique. The sheet is positioned on metal, wood or metal equipment, which .

Sheet metal forming at elevated temperatures, or so-called sheet metal warm/hot forming, is a relatively new forming process to make sheet metal parts with low mass. An accurate and convenient .SHEET METAL FORMING. Staub Manufacturing Solutions is the preferred fabrication supplier of top OEMs. An ISO 9001:2015 certified company with over 20 years of experience, Staub has comprehensive sheet metal forming capabilities and is known for delivering exceptional results.. Our highly skilled operators utilize CNC press brakes with independent, programmable 6-axis . #2. Sheet metal forming. Sheet metal forming involves the application of tensile and shears forces to fabricate sheets, plates, and strips to a desired possible shape using a set of tools. The punch and die are used as tools in the fabrication process.

Opening the Model and Inserting a Forming Tool. Next, you open a sheet metal part and add the formed louver from the Design Library. Specifying the Louvers. Next, you specify the louver rotation angle and insert two more identical louvers. Replacing Forming Tools. Next, you replace the louver forming tool with an extruded hole forming tool.Sheet Metalworking: Sheet metalworking processes are forming and cutting operations performed on metal sheets, strips, and coils. The surface-area-to-volume ratio of the starting metal is high; thus, this ratio is a useful means to distinguish bulk deformation from sheet metal processes.Sheet metal stamping is a cold-forming process using presses and dies to shape materials. It works with various metals, including stainless steel, carbon steel, aluminum, brass, and copper. Stamping combines cutting and forming techniques like bending, punching, embossing, and flanging to produce complex components quickly. .

Sheet metal forming is a highly versatile and widely used manufacturing process that involves shaping metal sheets into the desired parts and products. This intricate process plays a crucial role in various industries, including aerospace, automotive, electronics, and medical equipment manufacturing.Sheet Metal Forming. Application ID: 11208. This example benchmarks a NAFEMS validation model of a friction contact problem with an elastoplastic material model. A thin metal sheet is forced into a die by a punch. Both the compressing displacement and the release of the punch are modeled in order to compute the forming angle (at the maximum .

sheet metal layout drawings

sheet metal forming types

Forming of shallow parts using rubber tools. Maziar Ramezani, Zaidi M. Ripin, in Rubber-Pad Forming Processes, 2012. 4.1 Introduction. Sheet metal forming is a costly manufacturing process that is widely used in different industries. Many small companies are required to manufacture curved products and shallow parts with fine details in a small lot size which leads to both a .

Forming Limits and Splits: Reading into Sheet Metal Behavior. T he use of simulations is presently growing in manufacturing companies in today’s world, and the specific segment of stamping is no exception. In this article Adilson Calmona, Junior Application Engineer from AutoForm Brazil, takes us deeper by emphasizing the importance of post-processing in .

sheet metal forming process pdf

sheet metal forming press dies

sheet metal forming pdf

Know the size of the conduit that enters the box. For straight pulls, you multiply the conduit diameter by 8 to get the width of the face where the conduit enters.

forming metal sheet|sheet metal layout drawings