metal fabrication drawings This article will provide a series of key sheet metal design and fabrication guidelines to help engineers and designers understand how to maximize the use of the characteristics of metal sheets, ensuring the feasibility . Is there a limit to how many junction boxes can be used on a circuit/run? I'm thinking it will be easier to just drop the wire from each receptacle straight down into the basement into a junction box that is directly below each one.

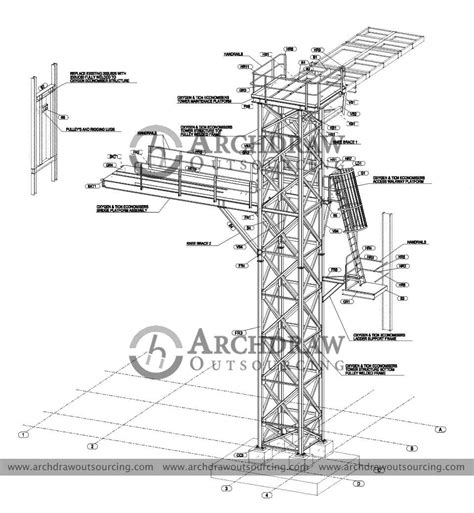

0 · structure fabrication drawing

1 · structural steel shop drawings

2 · structural steel fabrication drawings

3 · structural steel detail drawings

4 · structural shop drawings

5 · sheet metal design drawings

6 · metal fabrication drawing symbols

7 · how to read fabrication drawings

Tyco Electronic's Non-metallic splice and tap kits provide a fast and reliable method for splicing or tapping 2 wire w/ ground and splicing 3 wire w/ground non-metallic cables up to 300 volts. They are

5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. Follow these best practices next time you create a sheet metal fabrication drawing to help your shop turn the project around quickly: 1. .Interpreting metal fab drawings is a course that introduces the principles of interpretation and application of industrial fabrication drawings. Basic principles and techniques of metal fabrication are introduced by planning and .

Two-dimensional (2D) drawings are fundamental in the sheet metal fabrication sector. These drawings are graphical representations of the final product, carrying comprehensive details about dimensions, material specifics, . This article will provide a series of key sheet metal design and fabrication guidelines to help engineers and designers understand how to maximize the use of the characteristics of metal sheets, ensuring the feasibility .This article will focus on how to prepare accurate and easy to interpret sheet metal drawings so that your parts come out in spec every time. As a bonus, the best practices included in this article can help you establish a better working . Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including .

Interpreting metal fab drawings is a course that introduces the principles of interpretation and application of industrial fabrication drawings. Basic principles and techniques of metal fabrication are introduced by planning and .Interpretation of Metal Fab Drawings (Moran) This text is disseminated via the Open Education Resource (OER) LibreTexts Project (https://LibreTexts.org) and like the hundreds of other . Unlock the secrets to precise fabrication with our expert guide on detailing sheet metal shop drawings. Enhance accuracy and efficiency in your projects. Read more!

Welding and Metal fabrication drawings are specific to ease out the welding and metal assembling and installation processes. These drawings provide detailed instructions for welders, showcasing weld types, sizes, .Structural fabrication is the design, detailing, and creation of parts, assemblies, building systems, or structures from steel, concrete, or other materials.Prefabrication helps to reduce waste and speed installation and .Fast and easy sheet metal shop drawing services. 3D duct drawing with sizes of duct, part number, and material list for parts for fabrication. Search for: 610-287-1542 [email protected] Drawings will need to be converted to a flat pattern for fabrication, however, and 2D drawings are far more useable in sheet metal manufacturing. Where 3D drawings are used, they should be made with a sheet metal module, and good design practices should be followed so that the 3D dimensions match the 2D design.

1. Interpreting metal fab drawings . Interpreting metal fab drawings is a course that introduces the principles of interpretation and application of industrial fabrication drawings. Basic principles and techniques of metal fabrication are introduced by planning and construction of fixtures used in fabrication from drawings. Basic tools and Benefits of Sheet Metal Fabrication Drawings. Investing in high-quality sheet metal fabrication drawings yields a multitude of benefits throughout the manufacturing process: 1. Ensuring Accuracy and Reducing Errors: Fabrication drawings serve as the single source of truth for the entire manufacturing team. They communicate crucial details like .

1.1: Interpreting metal fab drawings 1.2: Blue Print Review 1.3: Joint types and Terminology 1.4: Basics of Welding Symbols 1.5: Supplementary Welding Symbols 1.6: Fillet Weld Symbols 1.7: Groove Welding Symbols 1.8: Plug Weld symbols 1.9: Spot, Seam, Stud Welding Symbols 1.10: Edge Weld Symbols 1.11: Process and Method 1.12: Pipe Symbols 1.13 . Sheet metal shop drawings are blueprints for metal fabricators that play a central role in aligning the shop floor operations with the design intent. Detailed shop drawings not only streamline the fabrication process but also mitigate costly errors, delays, and reworks and ensure that every piece fits seamlessly into the larger assembly. . Interpreting metal fab drawings is a course that introduces the principles of interpretation and application of industrial fabrication drawings. Basic principles and techniques of metal fabrication are introduced by planning and construction of fixtures used in fabrication from drawings. Basic tools and equipment for layout fitting of welded .Book Description: Interpreting metal fab drawings is a course that introduces the principles of interpretation and application of industrial fabrication drawings. Basic principles and techniques of metal fabrication are introduced by planning and construction of fixtures used in fabrication from drawings. Basic tools and equipment for layout .

At Toledo Fab, our mission is to deliver innovative, high-quality solutions that are tailored to meet the unique needs of every client. As a flexible, small business, we pride ourselves on the ability to adapt quickly, providing personalized service that larger companies often can’t match.. We are committed to maintaining the highest standards of quality in everything we do, from design .Free Metal Fabrications Architectural CAD drawings and blocks for download in dwg or pdf formats for use with AutoCAD and other 2D and 3D design software. By downloading and using any ARCAT CAD drawing content you agree to the following license agreement. Metal Fabrications, Brackets - Center Levered . “ Sheet metal fabrication drawing is a valuable process for making final-use products. Accuracy in drawing aluminum ensures smooth production, efficient material use, and high-quality standard parts.” . This guide will focus on the aluminum sheet metal drawing process, the techniques used, the sectors that use the process, the benefits of .

cnc machining parts buyer supplier

Metal Fabrication Step One: Drawing. We use Solidworks to draw and cut parts. We can also use files from a variety of other programs as long as they can be exported and saved as one of the following vector-format file types: STEP files (preferred) DXF; DWG; To cut parts, we need one of the accepted file types listed above.*

structure fabrication drawing

Metal fabricators estimate costs based on drawings and details. Get accurate custom metal fabrication quotes by sharing as much as possible. Metal fabricators estimate costs based on drawings and details. Services. Design; Cutting .

The deep drawing process in sheet metal fabrication is highly dependent on the precision and quality of die design. As one of the primary determinants of the final product’s quality and dimensional accuracy, the die . Fabrication as a service is only as good as the drawings that fabrication is based on. A simple fabrication drawing must be precise in order to be easily understood and ultimately effective when viewed and followed by the shop. There are various levels of detail and quality involved, especially as you debate fabrication drawing versus shop drawing, but the following . One of ESC’s Engineering capabilities in metal fabrication is to produce all types of CAD drawings in 2D and 3D models, including visualizations using Finite Element Analysis (FEA) system. It may not be a significant edge in the first place, since almost all fabrication companies have the ability to do the same. But here’s the difference – in ESC, our engineering .

cnc machining part quotes

Getting the correct way of dimensioning in sheet metal fabrication drawings. Best design practices should be followed so that the 3D dimensions match the 2D design. This is of course, now much easier to do with modern CAD software and tools. The following reference pictures and information illustrate the correct dimensioning information to give .This collection includes structural metal framing, metal joists, metal decking, cold-formed metal framing, and decorative metal. Explore our catalogue for comprehensive sheet metal CAD drawings available in both 2D and 3D formats, supporting your metal construction needs with precision and quality. collapse Expand Improve Your Metal Fabrication Design Software Process. A particular type of metal fabrication software, called metal fabrication design software, can be used during the planning stages. These options can create 2D drawings and diagrams, handle computer-aided designs (CAD), and provide an electronic method for making and modifying parts.Steel structure fabrication drawings refer to detailed drawings used to guide the manufacture, assembly and construction of prefab steel building projects. . Metal Buildings design from Havit Steel provides an optimized solution for your project. Our professional team is ready to serve any buildings. We can provide you with the most efficient .

Metal fabrication is a manufacturing process used to shape metal into parts or end products. It usually consist of three phases: 1) design, where shop drawings are created to the intended measurements; 2) fabrication, which involves cutting, bending, and/or assembling; and, 3) installation, where the end product or structure is put together . Many metal fabricators bid on jobs by submitting drawings, and if they are awarded the contract, they build the project. Once a contract has been awarded, metal fabricators begin the planning stages by ordering the correct materials and having an engineer program CNC machines for the project.Sheet metal parts often require multiple manufacturing processes to produce correctly. Because of this added complexity sheet metal drawings can be particularly tricky to create. This article will focus on how to prepare accurate and easy to interpret sheet metal drawings so that your parts come out in spec every time. Metal Fabrication Drawings. These illustrate the various metal components that are going to be used in your building, with details on manufacture, supply, assembly and installation. They comprise of fabrication shop drawings and sheet metal drawings. Single Part Drawings.

CAD drawings for sheet metal fabrication. Sheet metal products have customized fabrication approach based on the type of metal, sheet thickness, process of fabrication, tolerances etc. Fabricators get caught up in perfecting the final product .

structural steel shop drawings

Small terminal junction boxes designed to facilitate electrical connections in hazardous areas. Designed for use in Zone 1 or 2 areas, where flammable gases or vapors are present either .

metal fabrication drawings|structural steel detail drawings