cnc machine coolant The significance of coolant in CNC machining cannot be overstated. By selecting the appropriate coolant type and managing it . In addition, we’ll also take on several popular toolbox materials such as metal, aluminum, and plastic and how to clean them. Now, returning to the stainless-steel toolbox, you can clean it with stuff you can find around your household.

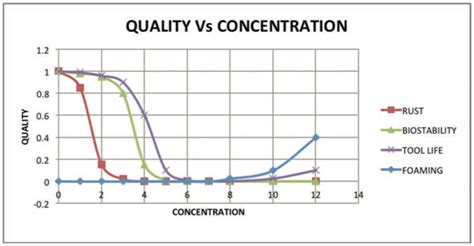

0 · machine coolant concentration chart

1 · coolant tank for cnc machine

2 · coolant system for milling machine

3 · coolant mixers for cnc equipment

4 · coolant concentration for cnc machines

5 · cnc machine coolant suppliers

6 · best semi synthetic machine coolant

7 · best coolant for cnc machine

Get a uni bit and drill. There should be two holes inside the box where the bracket is. Use the bit on the two holes to make them larger and the box will fall off. Yup that’s I decided to do, got a good quality hard metal bit and it went through those rivets in less then 30 seconds.

machine coolant concentration chart

Here, we’ll address this by breaking down the functions of coolant, the importance of choosing the right one for your CNC machine, and delve deeper into one of the popular types – soluble oils. Understanding the Role of Coolant . It’s important to choose the right type of CNC machining coolant based on your specific machining requirements. Consider factors such as cooling capacity, lubrication, corrosion prevention, and compatibility with the material .

someone who works with sheet metal

The significance of coolant in CNC machining cannot be overstated. By selecting the appropriate coolant type and managing it . Coolants for CNC machines help achieve optimal efficiency in a CNC shop. These coolants help reduce heat build-up, lubricate the cutting tool, and prevent discoloration and failure in machining processes such as CNC . Selecting the right CNC coolant is crucial for top machining performance. Coolants impact tool life, efficiency, and fluid consumption by reducing heat, friction, and debris. Oil-based, water-based, and synthetic .

The selection, monitoring, and maintenance of CNC machining coolant are crucial for maintaining temperature control, chip evacuation, lubrication, and extending tool life. Read on to learn more about the different . This article provides a comprehensive look at the types of CNC machine tool coolants available, their uses across industries, the importance of selecting the right coolant, .

Explore the crucial role of coolant in CNC machining operations, understanding how it dissipates heat, lubricates, and prevents tool wear. Learn about coolant types, formulations, and why consistent application is essential . In selecting the appropriate coolant for CNC machines, there are several key considerations. First and foremost is material compatibility . The coolant selected must match with the materials being machined to ensure . The Trimsol is a really good all arount coolant, that is exceptionally good for it's longevity.I run a Test and Eval shop where sometimes a month or 2 go by without using a particular machine. We check the coolant (make sure to top it up) once or twice a month. regards

I have a mill center that holds 40 or so gallons of coolant and use coolant MB50/50 (it's OK stuff will find better soon). What is the proper method of disposal of used coolant? Thanks In advance! Eric Similar Threads: Coolant Disposal; Need Help!-Coolant Disposal; Proper Coolant Maintenance/disposal; Disposal of old coolant; Coolant . Thanks guys, corrosion was my niggling worry Geof. Mazak, thanks for the advice. I'll change coolant, wondered why mine was so cheap and now I know the answer My problem is I don't use the mill for like two weeks, most of the stuff I do is diamond machining on a different beast, so my mill can be sat there for like two weeks with the coolant suppurating. Machine -> coolant collector -> robust filter -> fine filter -> tank -> Pump -> Spindle in -> Spindle out -> modular coolant nozzle In some my spindles modular nozzle comes direct from spindle, others have hose between. Pump is small 12v brushless, plastic (eBay), hose 6mm ID, When spindle starts - at the same time coolant pump does. I recently put a machine in a space that's not heated all the time and need to keep the coolant from freezing. Thanks, Ken Similar Threads: How to drill a hole using through coolant and using outside coolant on boring machine; adding coolant pump; Adding a coolant pump to my new lathe; Need Help!-Anti Freeze mix for Laser cooling system

Use a skimmer or coalescing filter system such as this : Keller Products, Inc. for removing tramp oil and install a small pump to keep the coolant circulating when the machine is not in use. An open mind is a virtue.so long as all the common sense has not leaked out. When I was a cnc operator (I am now a teacher in adult education, teaching CNC's), one of my bosses knew of a really simple solution to the coolant smelling bad. It consisted of bubbling shop air through the coolant. We just tapped a transparent air hose into the shop airline and weighted the end of the tube. Also, the area between the bottom casting and the cabinet will occasionally splash out and dribble onto the floor. A few restaurant trays keep things pretty clean. The machine came with a top cover which comes in handy when using a 1.97" facemill at 1939 rpm. The issue is now that the coolant drips on my head when doing a part change. CNC, Mechatronics Integration and Custom Machine Design “Logic will get you from A to B. Imagination will take you everywhere.” Albert E. 04-05-2012, 02:45 PM #4

For example I run my coolant at about 1/2 the pressure (the valve at the nozzles) when I am cutting steel with TIALN coated carbide bits. Let your chips dam up the two downhill runs into the chip tray. Add a damn there if needed. If your coolant is foaming, "filtering" it through chips before it hits the chip tray is very helpful to reduce foam. The Trimsol is a really good all arount coolant, that is exceptionally good for it's longevity.I run a Test and Eval shop where sometimes a month or 2 go by without using a particular machine. We check the coolant (make sure to top it up) once or twice a month. regards I have a mill center that holds 40 or so gallons of coolant and use coolant MB50/50 (it's OK stuff will find better soon). What is the proper method of disposal of used coolant? Thanks In advance! Eric Similar Threads: Coolant Disposal; Need Help!-Coolant Disposal; Proper Coolant Maintenance/disposal; Disposal of old coolant; Coolant .

Thanks guys, corrosion was my niggling worry Geof. Mazak, thanks for the advice. I'll change coolant, wondered why mine was so cheap and now I know the answer My problem is I don't use the mill for like two weeks, most of the stuff I do is diamond machining on a different beast, so my mill can be sat there for like two weeks with the coolant suppurating. Machine -> coolant collector -> robust filter -> fine filter -> tank -> Pump -> Spindle in -> Spindle out -> modular coolant nozzle In some my spindles modular nozzle comes direct from spindle, others have hose between. Pump is small 12v brushless, plastic (eBay), hose 6mm ID, When spindle starts - at the same time coolant pump does. I recently put a machine in a space that's not heated all the time and need to keep the coolant from freezing. Thanks, Ken Similar Threads: How to drill a hole using through coolant and using outside coolant on boring machine; adding coolant pump; Adding a coolant pump to my new lathe; Need Help!-Anti Freeze mix for Laser cooling system Use a skimmer or coalescing filter system such as this : Keller Products, Inc. for removing tramp oil and install a small pump to keep the coolant circulating when the machine is not in use. An open mind is a virtue.so long as all the common sense has not leaked out.

When I was a cnc operator (I am now a teacher in adult education, teaching CNC's), one of my bosses knew of a really simple solution to the coolant smelling bad. It consisted of bubbling shop air through the coolant. We just tapped a transparent air hose into the shop airline and weighted the end of the tube. Also, the area between the bottom casting and the cabinet will occasionally splash out and dribble onto the floor. A few restaurant trays keep things pretty clean. The machine came with a top cover which comes in handy when using a 1.97" facemill at 1939 rpm. The issue is now that the coolant drips on my head when doing a part change. CNC, Mechatronics Integration and Custom Machine Design “Logic will get you from A to B. Imagination will take you everywhere.” Albert E. 04-05-2012, 02:45 PM #4

coolant tank for cnc machine

coolant system for milling machine

solidworks sheet metal best practices

coolant mixers for cnc equipment

There are different types of fabric glue available, including temporary bonds, permanent holds, flexible and repositionable options, and those that offer a strong and durable bond.Whether it’s DXF files for 2D drawings, DWG files for intricate designs, STL files for 3D modeling, or the all-encompassing G-Code files, each file type plays a significant role in ensuring the CNC machine’s optimal performance and the creation of precise, high-quality .

cnc machine coolant|coolant concentration for cnc machines