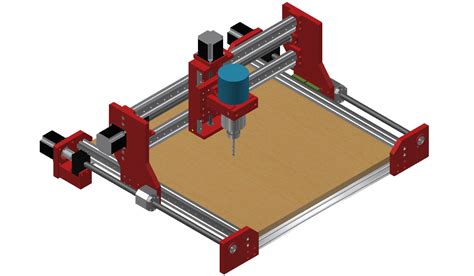

building a cnc machine pdf In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural .

Tuf-Tite® Distribution Box, 7-Hole, For Use With: For 3 in or 4 in PVC Pipe, HDPE, Black, 16 in L x 16 in W x 14-1/2 in H

0 · homemade cnc router machine

1 · homemade cnc machine plans

2 · do it yourself cnc machine

3 · build your own cnc router

4 · build your own cnc mill

5 · build your own cnc machine

6 · build your own cnc kit

7 · build your own cnc

Top 10 Best Metal Shops in Tucson, AZ - November 2024 - Yelp - Santa Rita Steel & Hardware, Ornamental Iron Company - Wrought Iron Repairs & Mobile Welding, Chris Nast Metalwork, .

I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing .For placement of various items such as motors, lead screws, bearings and other unique hardare items, go to the buildyourcnc.com website. Notes: All screw diameters and types will be 1 4" - .

In general if someone refers to a CNC “milling” machine they are referring to a metal cutting machine and if they say it’s a CNC "router" it means a machine made to cut wood, plastic or other soft materials. This instructable will show .

shearing machine for sheet metal

Guide on building a CNC machine with detailed instructions and tips for woodworking and metalworking enthusiasts.Building the KRMx01 CNC 1 Chapter 1 Getting Started Building your own KRMx1 CNC machine may seem intimidating at first, but this book will help to guide you through the process in . In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural .DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be .

Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials.

homemade cnc router machine

With a working area of 24"x48", you can build this for a lot less than the cost of a similar commercial CNC router. A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you .Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing and building this CNC milling machine.For placement of various items such as motors, lead screws, bearings and other unique hardare items, go to the buildyourcnc.com website. Notes: All screw diameters and types will be 1 4" - 20 unless specified otherwise. Hole dimeters and dimensions are seldomly repeated for simplicity.

In general if someone refers to a CNC “milling” machine they are referring to a metal cutting machine and if they say it’s a CNC "router" it means a machine made to cut wood, plastic or other soft materials. This instructable will show you how to build a CNC router.

Guide on building a CNC machine with detailed instructions and tips for woodworking and metalworking enthusiasts.Building the KRMx01 CNC 1 Chapter 1 Getting Started Building your own KRMx1 CNC machine may seem intimidating at first, but this book will help to guide you through the process in simple steps. Each chapter begins with a list of the parts needed .

In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.

DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials. With a working area of 24"x48", you can build this for a lot less than the cost of a similar commercial CNC router. A compact router, baltic birch plywood, some basic hardware, and an off-the-shelf electronics kit are all you need to build your own computer-controlled router.

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. ThisI know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing and building this CNC milling machine.

shallow single gang junction box

For placement of various items such as motors, lead screws, bearings and other unique hardare items, go to the buildyourcnc.com website. Notes: All screw diameters and types will be 1 4" - 20 unless specified otherwise. Hole dimeters and dimensions are seldomly repeated for simplicity.In general if someone refers to a CNC “milling” machine they are referring to a metal cutting machine and if they say it’s a CNC "router" it means a machine made to cut wood, plastic or other soft materials. This instructable will show you how to build a CNC router.Guide on building a CNC machine with detailed instructions and tips for woodworking and metalworking enthusiasts.Building the KRMx01 CNC 1 Chapter 1 Getting Started Building your own KRMx1 CNC machine may seem intimidating at first, but this book will help to guide you through the process in simple steps. Each chapter begins with a list of the parts needed .

In this project, I show you how I built my DIY CNC machine. All moving parts of the DIY CNC router are running on ball bearings while the structural parts are made with natural materials, namely birch plywood and solid beech wood.DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a documentation of how I built my CNC and is not to be mistaken as a tutorial for buidling a CNC.

homemade cnc machine plans

do it yourself cnc machine

Follow my carefully engineered plans to build this high performing, affordable CNC router. Full set of detailed drawings, instructions, and Bill of Materials.

sheet metal 4mm thick

build your own cnc router

8-Hole Distribution Box with Dosing Mid-wall (1 Inlet/ 7 Outlet, 28" x 15" x 14") (8DB-BAF)

building a cnc machine pdf|build your own cnc kit