additive manufacturing cnc machine Explore the differences between Additive Manufacturing and CNC manufacturing. Learn how to make smart choices when choosing from them for prototyping.

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings. If you’re not comfortable working with wires and electricity, you should hire an electrician to do this job for you.

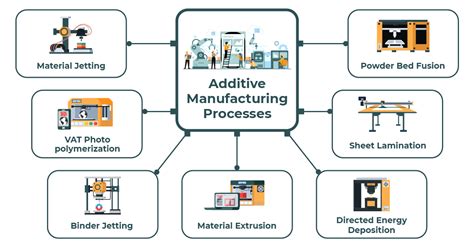

0 · types of additive manufacturing processes

1 · machine learning in additive manufacturing

2 · examples of additive manufacturing processes

3 · additive manufacturing materials list

4 · additive manufacturing machines for sale

5 · additive manufacturing 3d printing machines

6 · additive manufacturing 3d printer

7 · 3d metal printing machine

Power Distribution Boxes allow the protection of the primary circuits (pre-heating, electric steering, body computer etc) and the distribution of the engine power. All built into one single unit to optimize space.

For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal .

Additive manufacturing (AM) and CNC machining fulfill different needs in the manufacturing industry. The fundamental difference between AM and CNC machining lies in their approach: AM adds material to create an .

Understanding Additive Manufacturing and CNC Machining. Cutting through the jargon, the essence of Additive Manufacturing (AM) and Computer Numerical Control (CNC) Machining rests on three core principles: design, production, .

A clever combination: Additive manufacturing and CNC machining. DMG MORI has been a successful player on the market since 2013 with its combination of laser deposition welding and machining on the LASERTEC DED hybrid series . Its GEMINI machine for XXL hybrid additive manufacturing will also be on display at the booth. VLM Robotics hybrid robotic solutions can perform printing (Directed Energy .Explore the differences between Additive Manufacturing and CNC manufacturing. Learn how to make smart choices when choosing from them for prototyping.The combination of additive manufacturing technologies with conventional CNC machines enables DMG MORI to achieve four individual and demand-oriented process chains. CELOS completes the range of processes offered by the .

For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal components for industries including aerospace and defense through laser powder bed fusion (LPBF) on 20 metal additive machines. Additive manufacturing (AM) and CNC machining fulfill different needs in the manufacturing industry. The fundamental difference between AM and CNC machining lies in their approach: AM adds material to create an object, while CNC machining uses rotating tools to remove layers from blocks of material to shape the final piece.

Understanding Additive Manufacturing and CNC Machining. Cutting through the jargon, the essence of Additive Manufacturing (AM) and Computer Numerical Control (CNC) Machining rests on three core principles: design, production, and application. Bridging the gap between concepts and tangible products, these manufacturing technologies are reshaping .A clever combination: Additive manufacturing and CNC machining. DMG MORI has been a successful player on the market since 2013 with its combination of laser deposition welding and machining on the LASERTEC DED hybrid series machines. Its GEMINI machine for XXL hybrid additive manufacturing will also be on display at the booth. VLM Robotics hybrid robotic solutions can perform printing (Directed Energy Deposition, Cold Spray), welding, control and milling tasks. VLM Robotics’ range of CNC robotic machines can be seamlessly integrated into the production environment .

Explore the differences between Additive Manufacturing and CNC manufacturing. Learn how to make smart choices when choosing from them for prototyping.The combination of additive manufacturing technologies with conventional CNC machines enables DMG MORI to achieve four individual and demand-oriented process chains. CELOS completes the range of processes offered by the LASERTEC series, as an integrated software solution for CAM programming and machine control. A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining. CNC machining and additive manufacturing both have their advantages. Learn where AM is more beneficial, specifically for producing metal-forming dies.

metal fabrication fairfield ca

Motivation and requirements for CNC machining to deal with additive manufacturing and its integration in machine tools For Keselowski Advanced Manufacturing (KAM), success with additive manufacturing happens on the so-called “subtractive” machines. The Statesville, North Carolina, company produces highly engineered metal components for industries including aerospace and defense through laser powder bed fusion (LPBF) on 20 metal additive machines.

Additive manufacturing (AM) and CNC machining fulfill different needs in the manufacturing industry. The fundamental difference between AM and CNC machining lies in their approach: AM adds material to create an object, while CNC machining uses rotating tools to remove layers from blocks of material to shape the final piece.

Understanding Additive Manufacturing and CNC Machining. Cutting through the jargon, the essence of Additive Manufacturing (AM) and Computer Numerical Control (CNC) Machining rests on three core principles: design, production, and application. Bridging the gap between concepts and tangible products, these manufacturing technologies are reshaping .

metal fabrication gastonia nc

A clever combination: Additive manufacturing and CNC machining. DMG MORI has been a successful player on the market since 2013 with its combination of laser deposition welding and machining on the LASERTEC DED hybrid series machines. Its GEMINI machine for XXL hybrid additive manufacturing will also be on display at the booth. VLM Robotics hybrid robotic solutions can perform printing (Directed Energy Deposition, Cold Spray), welding, control and milling tasks. VLM Robotics’ range of CNC robotic machines can be seamlessly integrated into the production environment .Explore the differences between Additive Manufacturing and CNC manufacturing. Learn how to make smart choices when choosing from them for prototyping.The combination of additive manufacturing technologies with conventional CNC machines enables DMG MORI to achieve four individual and demand-oriented process chains. CELOS completes the range of processes offered by the LASERTEC series, as an integrated software solution for CAM programming and machine control.

A donut-shaped machine tool component called the AKZ FDS adapter illustrates the increasingly intricate links between additive manufacturing (AM) and CNC machining. CNC machining and additive manufacturing both have their advantages. Learn where AM is more beneficial, specifically for producing metal-forming dies.

types of additive manufacturing processes

machine learning in additive manufacturing

metal fabrication georgetown tx

Junction boxes come in various types, each designed for specific applications and environments. Understanding the different electrical box types and their uses is crucial for anyone involved in electrical work or home improvement projects.

additive manufacturing cnc machine|additive manufacturing machines for sale