drive a self tapping screw into electrical box by hand You can drill a 3/16" (or slightly smaller 11/64") pilot hole in the box and screw the self-tapping ground screw into it. If the grounding screws you have are not self-tapping, then . When welding stainless steel, there are several things you can do to limit distortion and the risk of warping. Keep in mind that MIG welding will introduce new material within the joint making it more prone to distortion. For this reason, TIG welding is the preferred method. 1.) Move quickly. Create the pool and weld immediately.

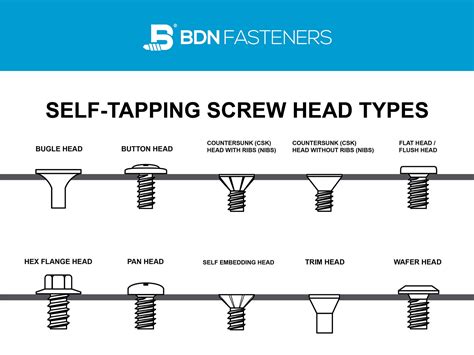

0 · self tapping screws instructions

1 · self tapping electrical screws

Welding thin sheet metal can be challenging because you need to obtain adequate fusion while preventing distortion and burnthrough. The key skill is to control the heat across the sheet metal to prevent defects.

You can drill a 3/16" (or slightly smaller 11/64") pilot hole in the box and screw the self-tapping ground screw into it. If the grounding screws you have are not self-tapping, then . We used those screws recently to mount some boxes to 5/16" steel tube. One other thing I would note is that a self drilling screw has the drill tip designed to drill its own hole in the .

You could always drive a self tapping screw into the back of the box to connect your ground wire if you can't find a 10-24. If the box is not grounded and a live conductor comes .You can insert self-tapping screws with either a hand-held or electric screwdriver. Before you use self-tapping screws, it's helpful, although not mandatory, to drill a pilot hole through the material. This ensures the screw will go in easily and will . Learn how to choose and use self-tapping screws for different materials. This guide covers thread-forming and thread-cutting screws, their sizes, styles, and installation methods. Self-tapping screws are a versatile and .

In this comprehensive guide, we will walk you through the step-by-step process of using self-tapping screws effectively, ensuring secure and long-lasting results. From selecting the right screws to mastering the installation technique, we’ll .For sheet metal enclosures like a formed electrical box they would use self tapping sheet metal screws like the OP describes. the holes give you a start so you don't end up on the edge, or the electrician can install/ remove or replace . By understanding the basics of self-tapping screws, identifying the materials and screw type, measuring the screw diameter, and following the step-by-step process, you can confidently drill the correct size hole every time. You can drill a 3/16" (or slightly smaller 11/64") pilot hole in the box and screw the self-tapping ground screw into it. If the grounding screws you have are not self-tapping, then you will also need to tap the hole, but most grounding screws self-tap.

We used those screws recently to mount some boxes to 5/16" steel tube. One other thing I would note is that a self drilling screw has the drill tip designed to drill its own hole in the metal, a self tapping screw is designed to go into a hole already drilled or punched in the metal. Guy attached a contactor into a box with Sheet metal self tapper. Seems to me it should be at minimum a Tapped hole with screw of a 32pi thread count. I don't see how the self tapper will securely fasten the contactor to the enclosure.

We're talking about two different screw types, shelf tapping sheet metal screws (non-compliant) and self tapping thread forming screws (compliant). Sheet metal screws do not comply with the minimum threads per inch. You could always drive a self tapping screw into the back of the box to connect your ground wire if you can't find a 10-24. If the box is not grounded and a live conductor comes into contact with the box, the breaker will not trip and the box will be live.You can insert self-tapping screws with either a hand-held or electric screwdriver. Before you use self-tapping screws, it's helpful, although not mandatory, to drill a pilot hole through the material. This ensures the screw will go in easily and will be positioned correctly.

Learn how to choose and use self-tapping screws for different materials. This guide covers thread-forming and thread-cutting screws, their sizes, styles, and installation methods. Self-tapping screws are a versatile and reliable fastening solution for . In this comprehensive guide, we will walk you through the step-by-step process of using self-tapping screws effectively, ensuring secure and long-lasting results. From selecting the right screws to mastering the installation technique, we’ll cover everything you need to know.

For sheet metal enclosures like a formed electrical box they would use self tapping sheet metal screws like the OP describes. the holes give you a start so you don't end up on the edge, or the electrician can install/ remove or replace the . By understanding the basics of self-tapping screws, identifying the materials and screw type, measuring the screw diameter, and following the step-by-step process, you can confidently drill the correct size hole every time. You can drill a 3/16" (or slightly smaller 11/64") pilot hole in the box and screw the self-tapping ground screw into it. If the grounding screws you have are not self-tapping, then you will also need to tap the hole, but most grounding screws self-tap.

self tapping screws instructions

We used those screws recently to mount some boxes to 5/16" steel tube. One other thing I would note is that a self drilling screw has the drill tip designed to drill its own hole in the metal, a self tapping screw is designed to go into a hole already drilled or punched in the metal. Guy attached a contactor into a box with Sheet metal self tapper. Seems to me it should be at minimum a Tapped hole with screw of a 32pi thread count. I don't see how the self tapper will securely fasten the contactor to the enclosure.

amc fabricated aluminum valve covers

We're talking about two different screw types, shelf tapping sheet metal screws (non-compliant) and self tapping thread forming screws (compliant). Sheet metal screws do not comply with the minimum threads per inch. You could always drive a self tapping screw into the back of the box to connect your ground wire if you can't find a 10-24. If the box is not grounded and a live conductor comes into contact with the box, the breaker will not trip and the box will be live.

You can insert self-tapping screws with either a hand-held or electric screwdriver. Before you use self-tapping screws, it's helpful, although not mandatory, to drill a pilot hole through the material. This ensures the screw will go in easily and will be positioned correctly. Learn how to choose and use self-tapping screws for different materials. This guide covers thread-forming and thread-cutting screws, their sizes, styles, and installation methods. Self-tapping screws are a versatile and reliable fastening solution for . In this comprehensive guide, we will walk you through the step-by-step process of using self-tapping screws effectively, ensuring secure and long-lasting results. From selecting the right screws to mastering the installation technique, we’ll cover everything you need to know. For sheet metal enclosures like a formed electrical box they would use self tapping sheet metal screws like the OP describes. the holes give you a start so you don't end up on the edge, or the electrician can install/ remove or replace the .

self tapping electrical screws

Plug welding is a method in which a round hole or slot is filled with a puddle of weld that is used to mate two parts or surfaces together. Plug welding has many drawbacks and isn’t a popular choice. Seam welding, or fillet welding, is one of the most common methods we use at Approved Sheet Metal.

drive a self tapping screw into electrical box by hand|self tapping screws instructions