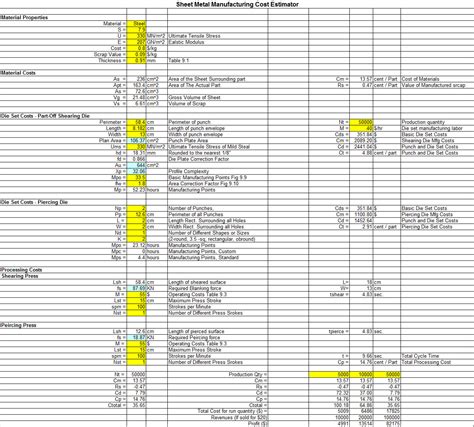

costing of sheet metal components Here, I will use some of the concepts and ideas of these articles and propose a method to estimate the production cost of a single sheet metal product, and of a full batch. Follow this link. $19.99

0 · sheet metal production cost calculator

1 · sheet metal parts cost estimator

2 · sheet metal manufacturing costs

3 · sheet metal manufacturing cost formula

4 · sheet metal manufacturing cost estimator

5 · sheet metal fabrication cost

6 · sheet metal cost calculator

7 · estimating sheet metal fabrication costs

In this post, we will explain four type CNC offset in CNC machining, you will know what it’s and the main setting. 1. Geometry Offset. Geometry offsets are mainly used for programming zero assignments.

Get a detailed breakdown of sheet metal fabrication costs, including material, labor, and equipment expenses. Learn how to save money on your next project with expert .

Consigned materials do not mean no material costs. Your sheet metal supplier still needs to receive the material, move it, store it, protect it and inventory it .Various factors influence sheet metal fabrication costs, each crucial in determining the final expenses for sheet metal parts. Manufacturers can gain insights into budget allocation and cost control by comprehending these cost . Here, I will use some of the concepts and ideas of these articles and propose a method to estimate the production cost of a single sheet metal product, and of a full batch. Follow this link.Understanding the costs of a sheet metal part will help you evaluate the choices each supplier is making to provide their price. First, let’s take a look at some of the key components of a sheet metal fabrication quote.

How to calculate the cost of sheet metal products considering cost of raw material, machining processes and the entire production cycle.

Get a detailed breakdown of sheet metal fabrication costs, including material, labor, and equipment expenses. Learn how to save money on your next project with expert tips from MachineMFG.Consigned materials do not mean no material costs. Your sheet metal supplier still needs to receive the material, move it, store it, protect it and inventory it until ready for use. Typically sheet metal suppliers add a mark-up percent to cover this cost which may or may not work to your advantage. Follo us o ...

cat litter electrical boxes

sheet metal production cost calculator

Throughout this article, we will explore the cost elements, offering a step-by-step guide on calculating sheet metal fabrication expenses. We will also analyze how the quantity of parts can influence the unit cost, providing practical .Various factors influence sheet metal fabrication costs, each crucial in determining the final expenses for sheet metal parts. Manufacturers can gain insights into budget allocation and cost control by comprehending these cost components. Here, I will use some of the concepts and ideas of these articles and propose a method to estimate the production cost of a single sheet metal product, and of a full batch. Follow this link. The sum of the costs associated with fabricating sheet metal comprises the price of the metal itself, the cost of designing and machining it, some overhead costs, and manufacturer profit margins. This article provides a straightforward method to .

In this blog post, we’ll address six frequently asked questions about cost estimating for sheet metal parts, and introduce you to a solution that can help streamline your estimating process and make your life easier as an estimator.Sheet metal fabrication prices are based on job time: Laser cutting is /minute, and each small hole is calculated at . CNC Pricing: /minute. CNC bending pricing: per side, double for large sides. Cold work welding costs per day, based on 50 kilograms per working day.

Understanding the costs of a sheet metal part will help you evaluate the choices each supplier is making to provide their price. First, let’s take a look at some of the key components of a sheet metal fabrication quote.How to calculate the cost of sheet metal products considering cost of raw material, machining processes and the entire production cycle.

Get a detailed breakdown of sheet metal fabrication costs, including material, labor, and equipment expenses. Learn how to save money on your next project with expert tips from MachineMFG.Consigned materials do not mean no material costs. Your sheet metal supplier still needs to receive the material, move it, store it, protect it and inventory it until ready for use. Typically sheet metal suppliers add a mark-up percent to cover this cost which may or may not work to your advantage. Follo us o ...

Throughout this article, we will explore the cost elements, offering a step-by-step guide on calculating sheet metal fabrication expenses. We will also analyze how the quantity of parts can influence the unit cost, providing practical .Various factors influence sheet metal fabrication costs, each crucial in determining the final expenses for sheet metal parts. Manufacturers can gain insights into budget allocation and cost control by comprehending these cost components. Here, I will use some of the concepts and ideas of these articles and propose a method to estimate the production cost of a single sheet metal product, and of a full batch. Follow this link.

The sum of the costs associated with fabricating sheet metal comprises the price of the metal itself, the cost of designing and machining it, some overhead costs, and manufacturer profit margins. This article provides a straightforward method to . In this blog post, we’ll address six frequently asked questions about cost estimating for sheet metal parts, and introduce you to a solution that can help streamline your estimating process and make your life easier as an estimator.

category 5e junction box

sheet metal parts cost estimator

cat6 junction box canada

sheet metal manufacturing costs

The most common types of sheet metal brakes are press brakes, magnetic brakes, and leaf brakes. Press brakes use hydraulic power to bend metal with varying degrees of precision and control. They can be used to form simple shapes like boxes or .

costing of sheet metal components|sheet metal manufacturing cost estimator