cnc machine preventative maintenance louisiana C3 Preventive Maintenance programs help our customers keep their machines running consistently. C3 has over 30 years of experience in repairing, maintaining, and running CNC machines of all kinds. C3 handles over 300+ . The National Electrical Code has published a chart that determines a junction box’s correct size, based on the number and size of the conductors it must accommodate. The size of a conductor is expressed as AWG (American .

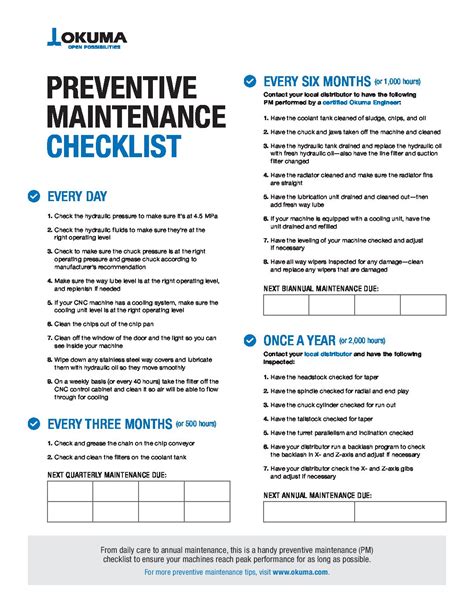

0 · okuma cnc machine maintenance checklist

1 · okuma cnc machine maintenance

2 · okuma cnc lathe maintenance

3 · cnc lathe maintenance checklist

A junction box is a standard electrical box that contains two or more spliced electrical cables. The box must have a removable, accessible cover. Junction boxes can be placed along electrical conduit, too.

Manufacturers throughout Louisiana partner with Methods to equip their shops with world-class CNC machine tools and engineering services including automation, preventive maintenance, .Proper hydraulic system service reduces CNC machine failure and maximizes . Optimize CNC machine performance with tailored maintenance from MachineTechs. Expert technicians, transparent pricing, and custom .C3 Preventive Maintenance programs help our customers keep their machines running consistently. C3 has over 30 years of experience in repairing, maintaining, and running CNC machines of all kinds. C3 handles over 300+ .

Manufacturers throughout Louisiana partner with Methods to equip their shops with world-class CNC machine tools and engineering services including automation, preventive maintenance, and technical support.Optimize CNC machine performance with tailored maintenance from MachineTechs. Expert technicians, transparent pricing, and custom plans. Contact MachineTechs today!

C3 Preventive Maintenance programs help our customers keep their machines running consistently. C3 has over 30 years of experience in repairing, maintaining, and running CNC machines of all kinds. C3 handles over 300+ machine repair and maintenance requests a year, demonstrating our extensive experience and trusted reputation in the industry.Do you cringe at the thought of taking your CNC machine out of production, losing precious time and money? Or are you meticulous about taking care of your investment so it will last a very long time? Here are some preventive maintenance (PM) tips to help keep your CNC lathe running at peak performance while avoiding unplanned downtime.

carters metal fabricators

Proper hydraulic system service reduces CNC machine failure and maximizes operating life. There’s no need to wait. Wherever your shop is located, our nationwide network of technicians and fully stocked inventory means you get faster service and support.

Why is Preventive Maintenance Beneficial for you? 1. Reduces downtime. 2. Saves you money. 3. Reduces complete breakdowns. 4. Extends the lifespan of your machine and cutting tools. 5. Reduces repair costs from unexpected breakdowns. 6. Minimize crashes or accidents. 7. Keeps production steady.Our preventative maintenance service technicians are experts at diagnosing problems before they occur. They perform a full CNC machine checkup. Electronics, motors, pumps, hydraulics, lubrication, axis movement, spindle, tool change functions and alignments are all inspected and finely tuned as part of our preventative maintenance service.Preventive Maintenance Programs to Fit Your Needs. Everyone knows that routine CNC machine maintenance is imperative to ensuring uptime. Absolute is proud to have created the most innovative Preventive Maintenance Program (PMP) in the industry with 3 levels of service to fit your company’s budget.

Maximize CNC machine uptime with KES Machine's expert service and maintenance. Preventive plans, 24/7 support, retrofits. 20+ years serving aerospace, automotive, and medical. Get a quote today!

Productivity provides CNC preventive maintenance for most makes and models of machine tools as well as FANUC robots. We offer flexible service levels and costs to provide the coverage you need. We’ll even tailor a service program that fits your exact needs and budget.Manufacturers throughout Louisiana partner with Methods to equip their shops with world-class CNC machine tools and engineering services including automation, preventive maintenance, and technical support.Optimize CNC machine performance with tailored maintenance from MachineTechs. Expert technicians, transparent pricing, and custom plans. Contact MachineTechs today!

C3 Preventive Maintenance programs help our customers keep their machines running consistently. C3 has over 30 years of experience in repairing, maintaining, and running CNC machines of all kinds. C3 handles over 300+ machine repair and maintenance requests a year, demonstrating our extensive experience and trusted reputation in the industry.Do you cringe at the thought of taking your CNC machine out of production, losing precious time and money? Or are you meticulous about taking care of your investment so it will last a very long time? Here are some preventive maintenance (PM) tips to help keep your CNC lathe running at peak performance while avoiding unplanned downtime.Proper hydraulic system service reduces CNC machine failure and maximizes operating life. There’s no need to wait. Wherever your shop is located, our nationwide network of technicians and fully stocked inventory means you get faster service and support.

Why is Preventive Maintenance Beneficial for you? 1. Reduces downtime. 2. Saves you money. 3. Reduces complete breakdowns. 4. Extends the lifespan of your machine and cutting tools. 5. Reduces repair costs from unexpected breakdowns. 6. Minimize crashes or accidents. 7. Keeps production steady.

Our preventative maintenance service technicians are experts at diagnosing problems before they occur. They perform a full CNC machine checkup. Electronics, motors, pumps, hydraulics, lubrication, axis movement, spindle, tool change functions and alignments are all inspected and finely tuned as part of our preventative maintenance service.Preventive Maintenance Programs to Fit Your Needs. Everyone knows that routine CNC machine maintenance is imperative to ensuring uptime. Absolute is proud to have created the most innovative Preventive Maintenance Program (PMP) in the industry with 3 levels of service to fit your company’s budget.

Maximize CNC machine uptime with KES Machine's expert service and maintenance. Preventive plans, 24/7 support, retrofits. 20+ years serving aerospace, automotive, and medical. Get a quote today!

okuma cnc machine maintenance checklist

carolina metal fabrication

okuma cnc machine maintenance

okuma cnc lathe maintenance

Steel is perhaps the most common metal used to make keys. But there are many others, it all depends on the location. For example, in Germany and Spain, steel is a predominant metal in making keys while in the US, Australia, and New Zealand .

cnc machine preventative maintenance louisiana|okuma cnc lathe maintenance