robot cnc machine tending Solutions for Robotic Machining and Machine Tending Robots. FANUC has a wide range of robots for manufacturing CNC machines to automate a variety of processes, including: . Their purpose is to keep the junction clear by preventing traffic from stopping in the path of crossing traffic. You MUST NOT enter a box junction unless your exit road is clear. But you can enter the box when you want to turn right and you’re .

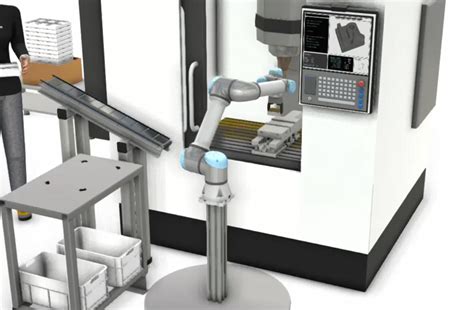

0 · universal robots machine tending

1 · universal robot tending cnc machine

2 · robotic arm cnc milling

3 · kuka milling robot price

4 · kuka cnc milling robot

5 · ceiling mounted robotic arm

6 · automatic loading and unloading robot

7 · automated cnc holster milling machine

$69.98

Solutions for Robotic Machining and Machine Tending Robots. FANUC has a wide range of robots for manufacturing CNC machines to automate a variety of processes, including: .Collaborative robots (cobots) are automation tools that can perform machine tending tasks and work alongside operators, helping fill persistent labor shortages while offering high-quality, consistent outputs 24/7.A machine tending robot or cobot is a robotic system designed to operate CNC machines, lathes, injection molding machines, presses, and other types of machinery. A CNC machine tending cobot loads raw materials into a machine .Top CNC Milling robot manufacturers FANUC. FANUC, headquartered in Japan, is one of the largest manufacturers of Industrial robots, including those for CNC Milling applications.They offer a wide range of articulated arm and SCARA .

universal robots machine tending

universal robot tending cnc machine

Robotic Machine Tending Cells for CNC Automation KUKA's System Partner Waybo has developed a series of pre-engineered machine tending cells featuring KUKA Robots that are ideal for automating high-mix low-volume manufacturing. Robotic CNC machine tending also automates the process, but offers more flexibility. Robots can handle variable parts and be quickly adapted to any changes in production. You can program a robot for pre- or post-machining tasks and reprogram it whenever a need arises. Robots are significantly better suited for dynamic or high-mix low-volume .

Machine tending robots are versatile and can handle various tasks, including loading and unloading parts in CNC machines, lathes, brake presses, and injection mold machines. They can also perform secondary tasks such as quality checks, cleaning, and finishing operations, enhancing overall production efficiency.

Finding qualified skilled labor for your CNC Machining operation is more difficult than ever. A robotic machine tool tending system can help maximize machine utilization and lower costs. Most importantly, a robotic machine tending system from KC Robotics will help you realize the Return on Investment (ROI) you need to succeed. +

A CNC machine tending robot is an automated system designed to load and unload parts from a CNC (Computer Numerical Control) machine, such as a milling machine, lathe, or grinding machine. These robots are typically used in manufacturing settings to increase efficiency, reduce labor costs, and improve safety.The LoadPro 4M CNC robotic tending solution has been developed for loading lathes and milling machines with machining cycle times of more than 5 minutes / machine. This phenomenal solution can attend between 4 and 8 CNC machines, even when different kind of parts are machined on each machine. The industrial robot model options are varied.While other, more complex solutions, involved deploying CNC machine tending robotic systems on gantry rails to service multiple machines. From CNCs to CMMs , Washing Systems , auto loaders, and or Laser Marking Systems , we can offer a wide range of CNC machine tending robots and equipment solutions to meet your specific needs

Contact North America. HALTER CNC Robotics LLC 21995 Fillmore Road Cascade, Iowa 52033 United States T: 800 314 8261 [email protected] VAT ID: US473961908

The Machine Tending Solution is the only solution you need to automate your CNC machines. Combined with our worldwide distribution network, you can automate a CNC machine in hours instead of weeks. . Using the Machine Tending Copilot algorithm, the robot finds the optimal path from point A to point B without colliding with the environment .Automate CNC machine tending with Vention's solutions. Increase productivity by automating loading and unloading of parts in CNCs and more. Platform. Software . Robotic machine tending was introduced to boost ROI, enhance production efficiency, and free employees for more fulfilling tasks. In just weeks, a compact robot cell with an .THE BENEFITS OF CNC INTEGRATION Lights Out Production: OB7 CNC machine robot arm is a cost-effective and easy-to-set-up solution that provides the fastest ROI of any other cobot on the market. By ensuring that spindles are always turning, gain the benefits of 24/7 operation with no breaks, absences, production stoppages, and lower operation costs. Caron Engineering MiConnect software to sequence the operation and control the CNC and Cobot; Lang fan for chip clearing; Here is a link to the video. . Generally machine tending robots have such little motion time compared to the machining operations that they last a long time. The biggest issues I have seen are from coolant contamination in .

FANUC robots for machine tending automate the loading and unloading of machine tools, enhancing productivity and precision. Key models like the M-20 series and CRX series are designed for various industries, including automotive, aerospace, and electronics. These robots offer features such as intuitive guidance, high reliability, and advanced .Our machine tending robots connect to any brand of cnc machine. Give us a call today to get started implementing robotic machine tending in your production. “Every time we’ve reached out, we got a real person to respond to us .Eliminate the complexity of deploying CNC machine tending applications and see results fast. With D:PLOY CNC, your complete machine tending application can be deployed in just hours. . PLOY CNC works with many leading .

robotic arm cnc milling

Having trouble finding qualified machine operators? Adding a simple robot to a 2 or 3 machine cell of new or existing CNC lathes or mills is the most common and most economical way to solve this problem.

Autonomous mobile robots can be integrated with stationary industrial robots when tending to machines in order to improve the flexibility, efficiency and productivity of the overall system. . Material or a ready-made blank is taken and inserted into the CNC machine, for example a grinding, milling or turning machine. Once machining has been .One of the most common applications is getting a CNC machine tending robot. Robots are used to load raw materials into computer-controlled cutting or milling machines and then retrieve the finished products. This automation not only streamlines the production process but also reduces the workload on human operators, increasing efficiency and .

CNC Machine Tending is any robotic or automated system that is used to load and unload parts or fixtures into and out of a CNC Machine in place of a human operator. Typical Machines that utilize Machine Tending include CNC Vertical Mills, CNC Horizontal Lathes, 5-Axis CNC’s, as well as Horizontals and machinery with integrated pallet-changing .

CNC MACHINE TENDING ROBOTS Robotic CNC Machine tending is a great solution when considering the benefits of contract machining and lean manufacturing. From placing raw parts into machines with or without the help of robotic vision to dropping finished parts off on a conveyor or a dunnage container once complete, Machine tending can be a .What is cobot machine tending? Cobot machine tending refers to collaborative robots, or cobots, helping out human workers with automated machine loading and unloading.. Instead of replacing human workers, cobots work side by side with them to handle repetitive, mundane tasks like feeding materials into CNC machines or removing finished parts. Cobots are lightweight, .The robotic automation systems as a whole is an attempt to reduce the involvement of humans in the production process, and the most efficient way to ensure that injuries on the working floor are reduced almost entirely is the use of robot machine tending. When the process of feeding materials into a machine is delegated to a robot instead of a human being, the probabilities of . Fanuc R2000 robot providing CNC machine tending. Fanuc R2000 robot providing CNC machine tending.

Start your automation process for Machine Tending with Collaborative Robot Applications. From CNC, Injection Molding and Press Machines. Skip to main content One Stop Shop for Collaborative Applications . Learn how to build a CNC Machine Tending application with this detailed video guide. You will be presented with the best practices .Especially good for CNC machine tending and quality inspection. CNC machines automation by robot cells . Businesses in the machining industry are more and more often using automation of CNC machining services. It is supported by almost any kind of CNC machines, such as lathes, milling machines, and plasma cutting machines, and made in order to .

Precision engineered insulated Twin Wall flue systems suitable for all woodburning and multifuel stoves. We supply a full range of Twin Wall components to create internal or external flue systems, available in black or stainless finishes and 5″ (125mm), 6″ (150mm), 7″ (175mm) and 8″ (200mm) internal diameters.Rare NYC Twin Towers WTC Lighted Mirror Motion Picture w Sound Frame Brooklyn Bridge.Water appears to move with water sound - not a very good sound, in my opinion, but .

robot cnc machine tending|kuka cnc milling robot