cnc machine for composities This guide explores the basics of composite CNC machining, explaining the fundamental properties of composite materials, constituting elements, and types of composites .

We’re the most driven, transparent, tech-savvy group of fabricators you’ve ever met. We provide precision metal fabrications from sheet metal to laser cut tubing for a broad range of industries, with our primary focus being in aluminum, stainless steel, galvanized and mild steel components.

0 · Types of CNC Machines for Advanced Composites

1 · Machining of Composite Materials

2 · Machining Carbon Fiber: Quick Guide [ Composites, Drilling,

3 · Dehoff 2555

4 · Composite Materials and Types of Machining

5 · Composite CNC Machining: A Detailed Overview

6 · CMS: 5

7 · CMS North America

8 · Best practices in the CNC machining of composites

Peak Roofing, Inc. Houston, TX Entryway Cover: Click Images to Enlarge. Copper Chimney Cap

Types of CNC Machines for Advanced Composites

Gain actionable insights to automate your composite production planning, increase plan accuracy, respond quickly to production issues and leverage simulations supporting strategic decisions and growth in composites. In advanced composite manufacturing, different types of CNC machines are used to meet diverse production needs. These include milling machines, turning machines, router machines, plasma cutters, laser cutters, .

sheet metal direct

CNC Machining composites with Datron. There are two basic technologies to choose from in machining composites: rotary machining and abrasive waterjet machining. .High speed and best-in-class accuracy 5-axis CNC machines for composites, aluminum and metal CMS Advanced Materials Technology is leader in the field of numerically controlled .The Dehoff 2555 is a CNC machine tailored for industries requiring precision in part manufacturing. Known for its reliability in metal processing, this machine serves industries like .

This guide explores the basics of composite CNC machining, explaining the fundamental properties of composite materials, constituting elements, and types of composites .Experience our 5-axis CNC machine's advanced technology, best-in-class accuracy, and top-notch precision. CNC machining centers ideal for composite materials, aluminum and metals processing.

Due to the abrasive and unique structure of composites, it is worth investing in a CNC machine with fully reinforced structural integrity and rigidity. A sturdy design reduces vibrations and tool deflection to provide top acceleration/deceleration speeds, long tool life, and low maintenance and repair costs over the lifetime of the machine . Gain actionable insights to automate your composite production planning, increase plan accuracy, respond quickly to production issues and leverage simulations supporting strategic decisions and growth in composites. In advanced composite manufacturing, different types of CNC machines are used to meet diverse production needs. These include milling machines, turning machines, router machines, plasma cutters, laser cutters, electrical discharge machines and 3D printing machines.

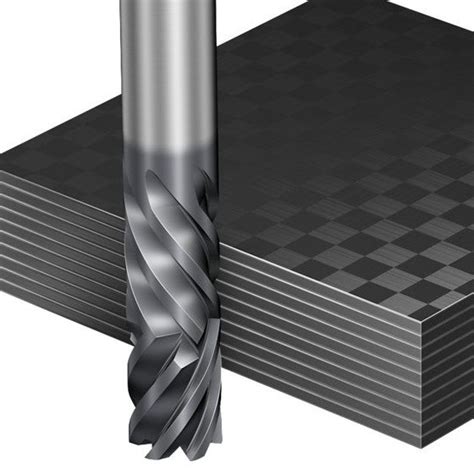

CNC Machining composites with Datron. There are two basic technologies to choose from in machining composites: rotary machining and abrasive waterjet machining. Rotary machining employs a cutting tool attached to a high-speed spindle driven by an NC-programmed machining center.High speed and best-in-class accuracy 5-axis CNC machines for composites, aluminum and metal CMS Advanced Materials Technology is leader in the field of numerically controlled machining centers for the working of advanced materials: composites, carbon fiber, aluminum, light alloys and metal.The Dehoff 2555 is a CNC machine tailored for industries requiring precision in part manufacturing. Known for its reliability in metal processing, this machine serves industries like automotive, aerospace, and manufacturing sectors. It can work on materials such as aluminum, steel, and composites. This guide explores the basics of composite CNC machining, explaining the fundamental properties of composite materials, constituting elements, and types of composites used in CNC machining. Continue reading to learn the basic steps of CNC machining composites, applications of CNC machined composite parts, and best practices for machining .

Experience our 5-axis CNC machine's advanced technology, best-in-class accuracy, and top-notch precision. CNC machining centers ideal for composite materials, aluminum and metals processing. CNC (Computer Numerical Control) machines are automated tools controlled by a computer executing pre-programmed sequences of machine control commands. These machines combine mechanical design with software-based control, allowing for high precision and repeatability in manufacturing processes.Find your composite cnc milling machine easily amongst the 74 products from the leading brands (MECANUMERIC, EMCO, Haas, .) on DirectIndustry, the industry specialist for your professional purchases. Due to the abrasive and unique structure of composites, it is worth investing in a CNC machine with fully reinforced structural integrity and rigidity. A sturdy design reduces vibrations and tool deflection to provide top acceleration/deceleration speeds, long tool life, and low maintenance and repair costs over the lifetime of the machine .

Gain actionable insights to automate your composite production planning, increase plan accuracy, respond quickly to production issues and leverage simulations supporting strategic decisions and growth in composites. In advanced composite manufacturing, different types of CNC machines are used to meet diverse production needs. These include milling machines, turning machines, router machines, plasma cutters, laser cutters, electrical discharge machines and 3D printing machines. CNC Machining composites with Datron. There are two basic technologies to choose from in machining composites: rotary machining and abrasive waterjet machining. Rotary machining employs a cutting tool attached to a high-speed spindle driven by an NC-programmed machining center.

High speed and best-in-class accuracy 5-axis CNC machines for composites, aluminum and metal CMS Advanced Materials Technology is leader in the field of numerically controlled machining centers for the working of advanced materials: composites, carbon fiber, aluminum, light alloys and metal.The Dehoff 2555 is a CNC machine tailored for industries requiring precision in part manufacturing. Known for its reliability in metal processing, this machine serves industries like automotive, aerospace, and manufacturing sectors. It can work on materials such as aluminum, steel, and composites. This guide explores the basics of composite CNC machining, explaining the fundamental properties of composite materials, constituting elements, and types of composites used in CNC machining. Continue reading to learn the basic steps of CNC machining composites, applications of CNC machined composite parts, and best practices for machining .Experience our 5-axis CNC machine's advanced technology, best-in-class accuracy, and top-notch precision. CNC machining centers ideal for composite materials, aluminum and metals processing.

CNC (Computer Numerical Control) machines are automated tools controlled by a computer executing pre-programmed sequences of machine control commands. These machines combine mechanical design with software-based control, allowing for high precision and repeatability in manufacturing processes.

Machining of Composite Materials

Machining Carbon Fiber: Quick Guide [ Composites, Drilling,

sheet metal distributor near me

Dehoff 2555

I would like to find a way to mount those weatherproof boxes to a length of unistrut to allow for future addition/modification without having to drill masonry over and over. Below is a sketch of what I'd like to do:

cnc machine for composities|CMS North America