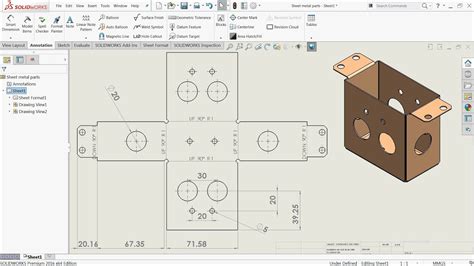

solidworks sheet metal part example Flattening and Folding the Part. You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an . Choose from our selection of box steel, including low-carbon steel rectangular tubes, multipurpose 304 stainless steel, and more. In stock and ready to ship.

0 · solidworks sheet metal pdf

1 · solidworks sheet metal examples

2 · solidworks sheet metal drawing pdf

3 · solidworks sheet metal download

4 · solidworks sheet metal basics

5 · sheet metal modeling in solidworks

6 · sheet metal in solidworks 2021

7 · sheet metal 3d sketch solidworks

If you find there is no ground wire in your electrical system, consider replacing outdated two-prong outlets, installing Ground Fault Circuit Interrupters (GFCIs), or exploring grounding through metal conduit or armored cable.

There are multiple methods for making sheet metal parts in Solidworks using the Sheet Metal tab. In this article, we will look at using the Sketched Bend feature and also the .Flattening and Folding the Part. You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an . By the end of this tutorial, you'll be well-equipped to design your own sheet metal components confidently in SolidWorks. Music: Inspire by Wavecont https://protunes.net Video Link: •.Forming tools are parts that act as dies that bend, stretch, or otherwise form sheet metal to create form features such as louvers, lances, flanges, and ribs. SOLIDWORKS multibody part .

Learn how Base Flange, Edge Flange, and Hem contribute to creating efficient, manufacturable, and precise sheet metal parts. 📏 Base Flange: Discover how to initiate sheet metal designs.Under Tangent edges, select Visible, and click OK. Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, then click OK to open a drawing sheet. .

In this video, we dive into the world of sheet metal parts, exploring the fundamentals and advanced techniques. Learn how to create precise bends, flanges, and cutouts, and optimize your.

SolidWorks Corporation: CSWP Advanced Sheet Metal Sample Exam. Certified SolidWorks Professional: Advanced Sheet Metal. (CSWP-SMTL) How to take this sample exam: The .Flatten Sheet Metal Part Example (VBA) This example shows how to flatten a sheet metal part. '----- ' Preconditions: ' 1. Open a sheet metal part. ' 2. Open the Immediate window. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .Set and Get Sheet Metal Part's Persistent Reference IDs Example (VBA) This example shows how to set and get persistent reference IDs on a sheet metal part. The entities in flattened and unflattened (folded) states of sheet metal in SolidWorks do not have the same properties, making it difficult to track entities across states of sheet metal.' 1) Sheet metal part is open. ' 2) Adjust paper template size, height, and width. ' ' Postconditions: ' Anew A1 sized drawing is generated with ' a flattened view of the sheet metal part ' with no bend lines showing. ' '-----Option Explicit . Public Enum swDwgPaperSizes_e

' 1) Sheet metal part is open. ' 2) Adjust paper template size, height, and width. ' ' Postconditions: ' Anew A1 sized drawing is generated with ' a flattened view of the sheet metal part ' with no bend lines showing. ' '-----Option Explicit . Public Enum swDwgPaperSizes_e'----- ' Preconditions: ' 1. Open a sheet metal part. ' 2. Select the sheet metal feature in the FeatureManager design ' tree. ' ' Postconditions: ' 1. Rolls back the sheet metal feature and selects the fixed face ' or edge, if either exists. ' 2. Rolls forward the sheet metal part.Flatten Sheet Metal Part Example (VBA) This example shows how to flatten a sheet metal part. '----- ' Preconditions: ' 1. Open a sheet metal part. ' 2. Open the Immediate window. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .Creating a New Sheet Metal Template. You can create new sheet metal templates for use with the Costing tool. Editing a Sheet Metal Template. You can modify Costing templates any time there are changes in cost structures. For example, if the price of steel increases, you can change the cost in the template. Costing Template Editor for Sheet .

Flatten Sheet Metal Part Example (VBA) This example shows how to flatten a sheet metal part. '----- ' Preconditions: ' 1. Open a sheet metal part. ' 2. Open the Immediate window. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. .

Contents. General. Use the General screen in the Costing Template Editor to set the units and currency options.. Material. Use the Material screen in the Costing Template Editor to set the materials you need to manufacture the sheet metal part.. Thickness. Use the Thickness screen in the Costing Template Editor to set the thickness and cost values for each class and material .Get Features of Multibody Sheet Metal Part Example (VBA) . ' 1. Open C:\Users\Public\Documents\SOLIDWORKS\SOLIDWORKS 2020\samples\tutorial\api\weldment_box3.sldprt. ' 2. Inspect the cut list folder. ' 3. Open the Immediate window. ' ' Postconditions: ' 1. Gets the number and names of the features in the .Get Sheet Metal Feature Data Example (VBA) This example shows how to get the sheet metal feature data from a sheet metal part created in SOLIDWORKS 2013 or later. '-----' Preconditions: ' 1. Open a sheet metal part created in SOLIDWORKS 2013 or later. ' 2. Open an Immediate window. ' ' Postconditions: Inspect the Immediate window to see whetherFlattening and Folding the Part. You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Completing the Sheet Metal Drawing. Next, add a view of the unfolded model.

Help Content Version: SOLIDWORKS Connected Tutorials (3DEXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. To report problems encountered with the help interface and search, contact your local support representative.Get Sheet Metal Feature Data Example (VBA) This example shows how to get the sheet metal feature data from a sheet metal part created in SOLIDWORKS 2013 or later. '-----' Preconditions: ' 1. Open a sheet metal part created in SOLIDWORKS 2013 or later. ' 2. Open an Immediate window. ' ' Postconditions: Inspect the Immediate window to see whethergeometries, the user has the option to use non-sheet metal feature tools and then use the Insert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude, As mentioned previously, Costing can calculate the cost associated with a variety of manufacturing processes, including sheet metal parts, machined parts, multibody parts, assemblies, molded plastic parts, casting, .

How to Use SolidWorks Miter Flange | SolidWorks Sheet Metal Tutorial #2. Sheet metal miter flange is also like edge flange helps to add one or more flanges on base flange sheet metal part. Miter flange is slightly different .'----- ' Preconditions: ' 1. Open a sheet metal part. ' 2. Select the sheet metal feature in the FeatureManager design ' tree. ' ' Postconditions: ' 1. Rolls back the sheet metal feature and selects the fixed face ' or edge, if either exists. ' 2. Rolls forward the sheet metal part.

'----- ' Preconditions: ' 1. Open a sheet metal part. ' 2. Select the sheet metal feature in the FeatureManager design ' tree. ' ' Postconditions: ' 1. Rolls back the sheet metal feature and selects the fixed face ' or edge, if either exists. ' 2. Rolls forward the sheet metal part.

Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Click Options (Standard toolbar).; On the System Options tab, click Drawings > Display Style.; Under Tangent edges, select Visible, and click OK.; Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, .

This example shows how to create an optimized, normal, cut extrude in a sheet metal part. //-----// Preconditions: // 1. Verify that the sheet metal part to open exists. // 2. Open the Immediate window. // // Postconditions: // 1. Opens the sheet metal part. // 2. Selects a face. // 3.

Let’s walk through it using an example of a battery tray designed for a radio-controlled car. SOLIDWORKS. 3D CAD . right-click on the main face of your SOLIDWORKS Sheet Metal part and select Export to DXF / DWG. Next, save the DXF file with your desired file name and location. In the options, .'----- ' Preconditions: ' 1. Open a sheet metal part. ' 2. Select the sheet metal feature in the FeatureManager design ' tree. ' ' Postconditions: ' 1. Rolls back the sheet metal feature and selects the fixed face ' or edge, if either exists. ' 2. Rolls forward the sheet metal part.

For example, if the part is to be painted, you can assign a cost to paint the entire part or specific faces of a part. If you are painting specific faces, include a cost per area such as dollars per square inch to paint the part. You can set custom operations in the sheet metal template and apply the operations automatically or manually.

steel box section suppliers northern ireland

Change Bend Radius of Sheet Metal Part Example (VBA) . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to our documentation team. The documentation team cannot answer technical support questions.Change Bend Radius of Sheet Metal Part Example (VBA) This example shows how to change the default bend radius of a sheet metal part. '-----' ' Preconditions: ' (1) Part document containing sheet metal part is open. ' (2) Sheet-Metal feature is selected. ' ' Postconditions: Default bend radius value is doubled. 'Under Sheet Metal Parameters: Select a face as the fixed face for the sheet metal part. Set the sheet thickness and default bend radius. Select Keep body if you want to keep the solid body to use in another Convert to Sheet Metal feature. When cleared, the body is consumed by the Convert to Sheet Metal feature.

solidworks sheet metal pdf

solidworks sheet metal examples

Single Gang Meaning ‘Single Gang’ or ‘1-Gang’ refers to a box that is wide enough to accommodate a switch. A ‘1-Gang Box’ can also hold a duplex receptacle.

solidworks sheet metal part example|sheet metal 3d sketch solidworks