blank development formula for sheet metal Sheet Metal Developed Blanks - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses several methods for determining the proper blank size when developing flat stock for bent sheet . $9.99

0 · sheet metal development length formula

1 · sheet metal design length formula

2 · sheet metal blank length formula

3 · sheet metal blank length calculator

4 · sheet metal bending formula

5 · metal sheet development formula

6 · metal sheet development calculation

7 · how to calculate a metal sheet

MIG is one of the best ways to weld 20-gauge sheet metal. MIG welding is one of the simplest to use for welding. It is an arc welding process that where you feed a solid wire electrode through a welding gun. Metal inert gas is then used to protect the weld from contaminants.

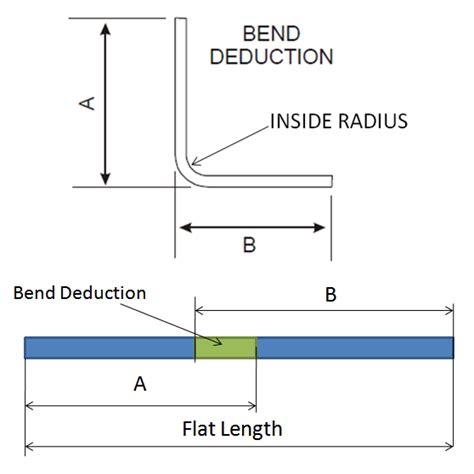

Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = Setback: The amount to be subtracted from the sum of the outside The following examples walk you through the flat-blank development methods. They apply bend functions to a simple, single-bend part, bent past 90 degrees complementary, to show how the complementary or . We are going to give two very simple formulas to calculate the neutral fiber in an “L” shape and another one for a “U” shape and we will see it with an example for each case. Formula: Development = Flat face A + Flat . To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: (Outside Diameter – Thickness) x 3.1416 = Length of Plate Required. (Inside Diameter .

Sheet Metal Developed Blanks - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses several methods for determining the proper blank size when developing flat stock for bent sheet .

With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert .To give users an understanding of sheet metal calculations in general and how they are used in SolidWorks, this article will review the following: The definition of both bend allowance and .

electrical concrete box

Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time.

Starting with the 2D cutting process needed to make a blank, then exploring forming operations necessary for various sheet metal features, and finally concluding with finishing and assembly considerations as well as how to .Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = Setback: The amount to be subtracted from the sum of the outside Sheet Metal Development Length Formula (Blank Size) Have you ever struggled with accurately unfolding sheet metal parts? This article explores the art and science behind sheet metal unfolding calculations.

The following examples walk you through the flat-blank development methods. They apply bend functions to a simple, single-bend part, bent past 90 degrees complementary, to show how the complementary or included angles are applied in the OSSB and ultimately to a layout.

We are going to give two very simple formulas to calculate the neutral fiber in an “L” shape and another one for a “U” shape and we will see it with an example for each case. Formula: Development = Flat face A + Flat face B + ¶ / 2 x (inner radius + neutral fiber) Let’s put an example with real measurements to do the calculation; To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: (Outside Diameter – Thickness) x 3.1416 = Length of Plate Required. (Inside Diameter + .Sheet Metal Developed Blanks - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses several methods for determining the proper blank size when developing flat stock for bent sheet metal parts, including: 1) Setbacks, bend allowances, and K factors which account for changes to part .With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert interior angle, flange lengths, K factor, inside radius, and material thickness.

To give users an understanding of sheet metal calculations in general and how they are used in SolidWorks, this article will review the following: The definition of both bend allowance and bend deduction methods and how each of them relates to the actual sheet metal geometry. Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time.

Starting with the 2D cutting process needed to make a blank, then exploring forming operations necessary for various sheet metal features, and finally concluding with finishing and assembly considerations as well as how to ensure your team puts out good designs that your manufacturers can understand and make at a high quality.Illustrated here is the development of a blank for parts having a standard 90 deg. bend. Shown is a common dimensioning method and calculation of a Setback (bend deduction) * SB = Setback: The amount to be subtracted from the sum of the outside Sheet Metal Development Length Formula (Blank Size) Have you ever struggled with accurately unfolding sheet metal parts? This article explores the art and science behind sheet metal unfolding calculations. The following examples walk you through the flat-blank development methods. They apply bend functions to a simple, single-bend part, bent past 90 degrees complementary, to show how the complementary or included angles are applied in the OSSB and ultimately to a layout.

We are going to give two very simple formulas to calculate the neutral fiber in an “L” shape and another one for a “U” shape and we will see it with an example for each case. Formula: Development = Flat face A + Flat face B + ¶ / 2 x (inner radius + neutral fiber) Let’s put an example with real measurements to do the calculation; To develop the blank flat length for a cylinder rolled from sheet or plate is quite simple: Essentially, you should calculate the centerline arc: (Outside Diameter – Thickness) x 3.1416 = Length of Plate Required. (Inside Diameter + .Sheet Metal Developed Blanks - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses several methods for determining the proper blank size when developing flat stock for bent sheet metal parts, including: 1) Setbacks, bend allowances, and K factors which account for changes to part .

electrical cover box home depot

With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert interior angle, flange lengths, K factor, inside radius, and material thickness.

To give users an understanding of sheet metal calculations in general and how they are used in SolidWorks, this article will review the following: The definition of both bend allowance and bend deduction methods and how each of them relates to the actual sheet metal geometry.

Learn how to accurately calculate bend allowance with our easy-to-understand formula. Improve your sheet metal bending operations and achieve precise results every time.

electrical cord cover box

sheet metal development length formula

These are American (Brown & Sharpe) Gauges.

blank development formula for sheet metal|sheet metal design length formula